(Vietnam)Oriental Motor Asia Pacific Pte. Ltd. - Manufacturer of Motion Control Products > Technical Support > Motor Selection Calculations 04

|

Selection calculation motor Motor Selection Formula

|

The following explains the required formulas for controlling a stepping motor or servo motor based on pulse signal.

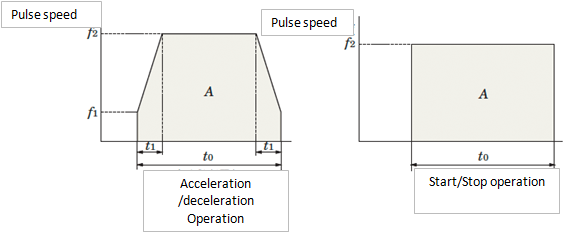

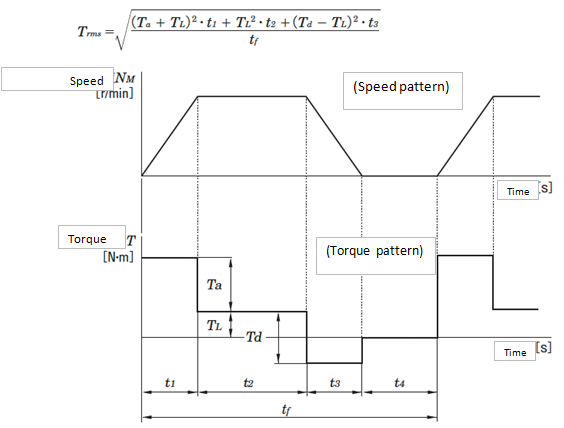

Operation pattern

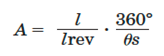

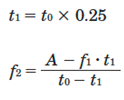

f1: Starting pulse speed [Hz] f2: Operating pulse speed [Hz] A: Number of working pulses t0: Positioning time [s] t1: Acceleration (deceleration) time [s] You can ask us to select the motor you need via home page. You can select what you need through online motor sizing application. More details can be found here. Formula of the Number of for Operating Pulses A [Pulse] The number of operating pulses is expressed as the number of pulse signals that add up to the angle that the motor must rotate to get the load from point A to point B.  ∫: Traveling amount between the from A to B point [m] ∫REV: Traveling amount per rotation [m/rev] ΘS: step angle [°] Formula for Operating Pulse f2 [Hz] The speed of operating pulse speed can be obtained from the number of operating pulses, the positioning time and the acceleration (deceleration) time. ① For Acceleration/deceleration operation

The level of acceleration (deceleration) time is an important point in the selection. The acceleration (deceleration) time cannot be set easily, because it correlates with the acceleration torque and acceleration/deceleration rate.

Initially, as a reference, calculate the acceleration (deceleration) time at roughly 25% of positioning time. (The calculation must be adjusted before the final decision can be made.)

② For Start/stop operation

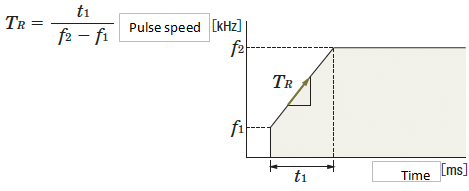

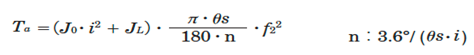

Formula of the Acceleration/Deceleration Rate TR[ms/kHz]

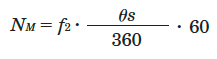

Calculate the pulse speed in full step conversion. For this formula, the speed is in [kHz] and the time in [ms]. Conversion formula for the Operating Speed NM [r/min] from the Operating Pulse Speed f2 [Hz]

More details can be found here. (http://www.orientalmotor.com.sg/om/support_tool_sg/acceleration/) Formula for the Acceleration of torque Ta[N・m]

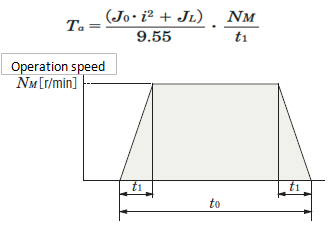

Common basic formula for all motors  < When calculating the acceleration torque for steeping motors on the basis of pulse speed> ①Acceleration/deceleration operation

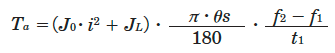

②Start/stop operation

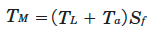

Formula for the Required Torque TM[N・m]

TM :Required torque[N·m] TL : : Load torque N·m] Ta : Acceleration torque[N·m] Sf : Safety factor Formula for the Effective Load Torque Trms[N・m]

|