Quality and Safety

Oriental Motor is committed to providing reliable and trustworthy products and related services based on the following basic quality principles and quality policy.

Quality Policy

Oriental Motor works to develop and standardize products that reflect our customer's demands and promotes quality improvements by maintaining a stable manufacturing process and ensuring constant improvements by personnel in their respective roles.

-

Continuous Improvement

All personnel recognize the importance of quality and implement continuous improvements in their respective workplaces through a smooth PDCA cycle. -

Customer Satisfaction

We aim for higher customer satisfaction by giving consideration to the needs of customers and reflecting those needs in the improvements to our products and services. -

Compliance with Laws and Regulations

We observe the laws, regulations, social requirements, and agreements made with our customers / partners. -

Quality Education

We place emphasis on product quality education and the creativity and ingenuity of our employees, and strive to acquire more skills and improve product quality.

To achieve the above, we will establish and operate a quality management system and strive for continuous improvement.

Established: January 6, 1994

Revised: April 1, 2023

Quality Management Systems

We are ISO 9001 and ISO 14001 certified and are creating an integrated management system.

The transition to the 2015 edition was completed during the 2016 renewal review.

Certification Status

| ISO 9001 | ISO 14001 | ISO 45001 | |

|---|---|---|---|

| Registration Date | February 23, 2005 *Date of certification for company-wide integration | December 20, 2019 | |

| Update Date | February 15, 2023 *Date of issuance of the latest registration certificate | December 20, 2022 | |

| Registered Plants |

|

Soma Office | |

| Certification Criteria | ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018 |

| Examination and registration organization | Japan Quality Assurance Organization (JQA) | ||

| Certification Number | JQA-QMA15799 | JQA-EM7425 | JQA-OH0309 |

Testing system to ensure product safety

Oriental Motor products comply with all major safety standards and laws in Europe, North America, Asia and other parts of the world. To ensure the safety of our products, we have established a product safety laboratory and an EMC test center at our Tsukuba Plant to test and evaluate compliance with safety standards and laws.

The product safety testing laboratory is independent from the business divisions and is governed by the international standard ISO/IEC 17025 Laboratory Management System, and is compliant with the European EN standards by the VDE (German Institute of Electrical Engineers), and by UL (Underwriters Laboratories) for American UL and Canadian CSA standards. At the same time, it is registered as an IECEE CTF Stage 2 laboratory, which conducts testing for IEC standards, the international standard for electrical equipment.

Rigorous and objective testing is conducted in-house, and the results are immediately fed back into product development and design. Through this product safety testing system, Oriental Motor offers safe products that can be used with confidence all over the world.

-

Product Safety Testing Laboratory (at the Tsukuba Plant) -

Locked-rotor testing (in the Product Safety Laboratory) -

EMC Test Center

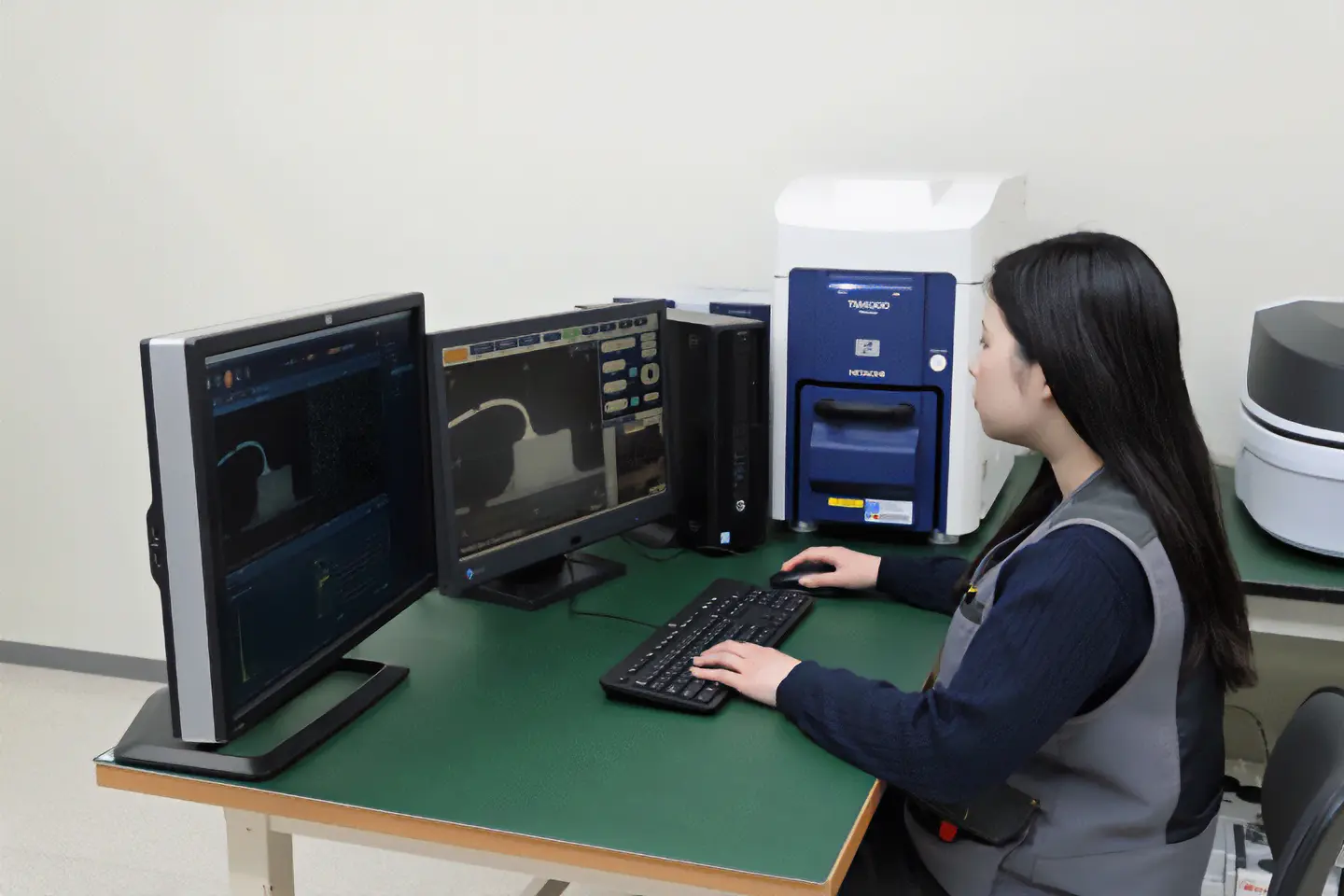

Testing system to ensure product reliability

The Reliability Test Building at the Tsukuba Plant has a variety of equipment for environmental testing, with dedicated engineers conducting the tests.

After testing is completed, a careful investigation and analysis is also performed to ensure that the product has the intended strength. The Design Division uses the results of this research and analysis to improve and refine the product.

Repeated design evaluations carried out in this manner enhance product reliability and provide customers with products that they can use with confidence.

Main owned evaluation facilities

Measurements

- 3D coordinate measuring machines

- Image measuring machines

- Roundness measuring machines

- Surface roughness contour measuring machines

Test Conditions

- Compact low-temperature constant-temperature chamber

- Motor shaft fatigue tester

- Highly accelerated life test (HAST)

- Combined environmental testing machine

- Thermal Shock Tester

- Salt spray tester

- Constant temperature and humidity chamber

- Drop test machine

Analysis

- Stereomicroscope

- Metallurgical microscope

- Scanning electron microscope (SEM)

- X-ray fluorescence analyzer (EDX)

- Infrared spectrophotometer (FT-IR )