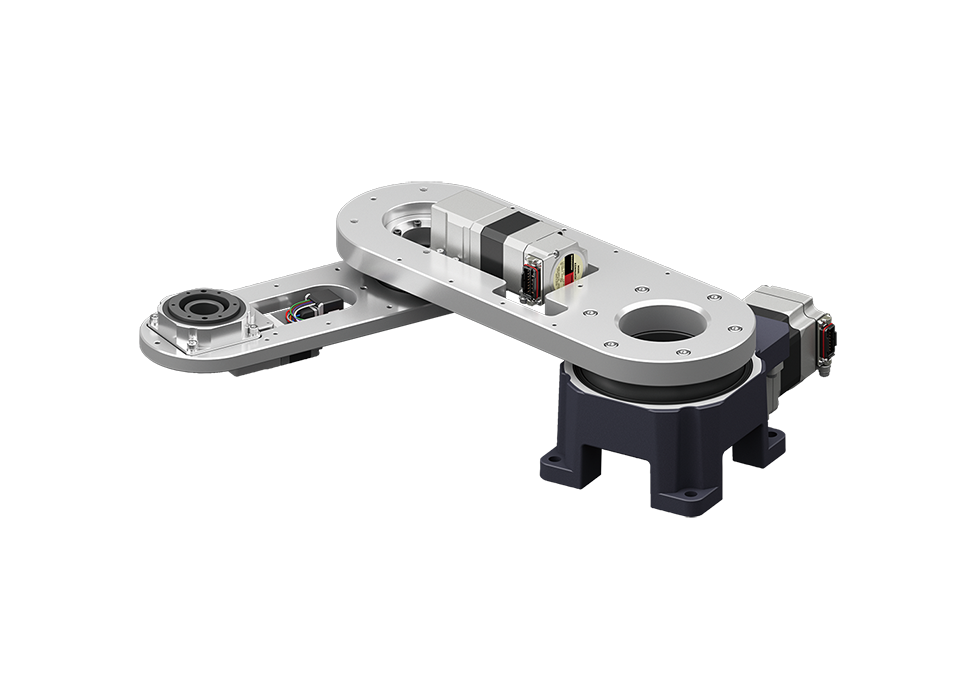

Small Robots OVR

3-Axis SCARA Robot

- Lightweight and Flat, With a Mass of 7.6 kg and a Height of 140 mm

- Able to Approach Tight Spaces

- The Third Arm Can be Freely Customized to Fit the Equipment

- Maximum Reach 410 mm, Payload 3 kg

- Drive Motor: AZ Series with battery-free built-in absolute encoder (DC input)

Tính năng |3-Axis SCARA Robot

- Flat SCARA Robot

- Customizable Design to Fit Your Equipment

- Easy-to-Control Robot Controller

- Using AZ Series With Battery-Free Built-In Absolute Encoder

- Useful Tools Before Installing Robots

- Specifications

- Dimensions/Motion Range Diagram

- Various Data

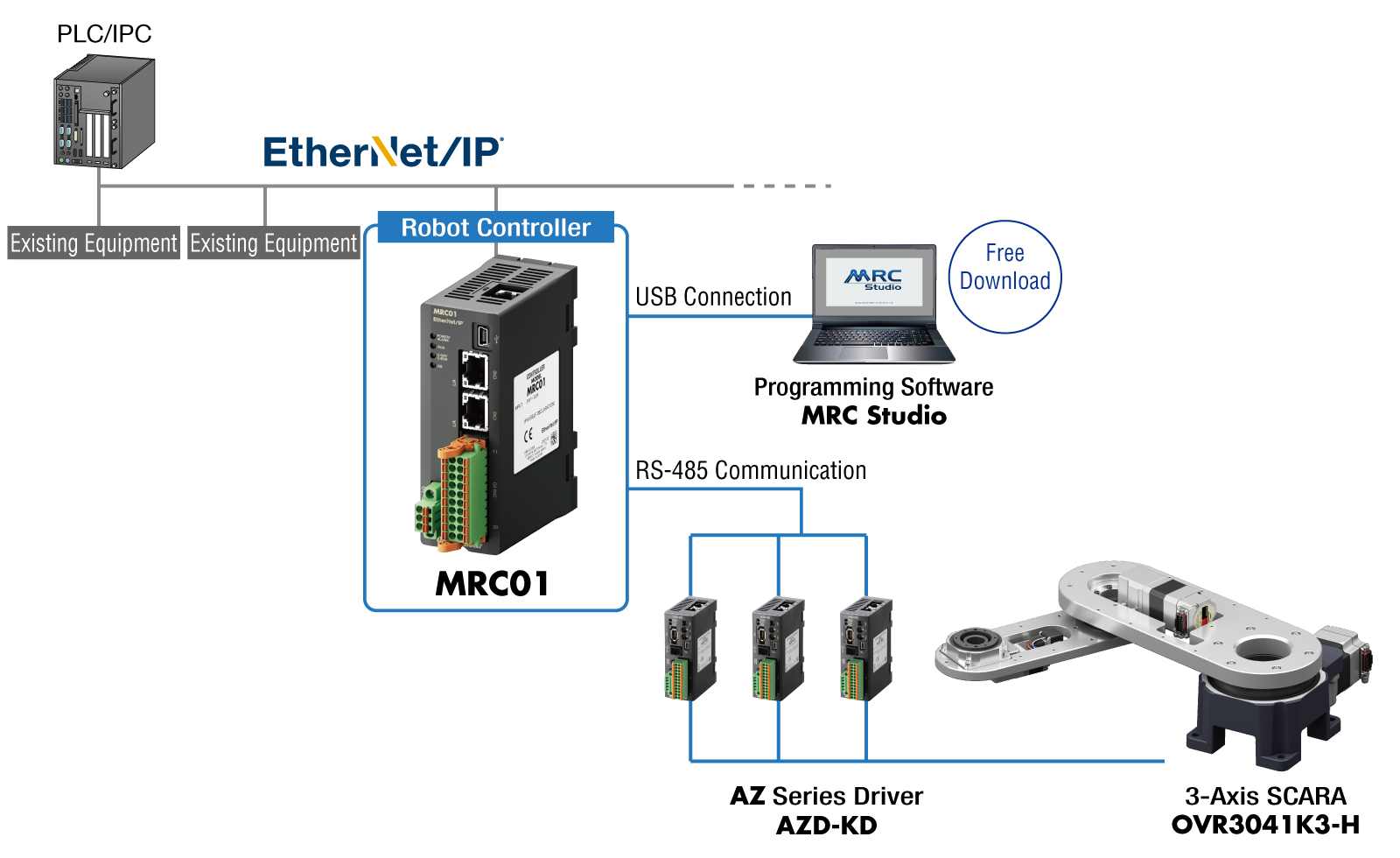

- System Configuration

- Mounting Bracket for 3-Axis SCARA

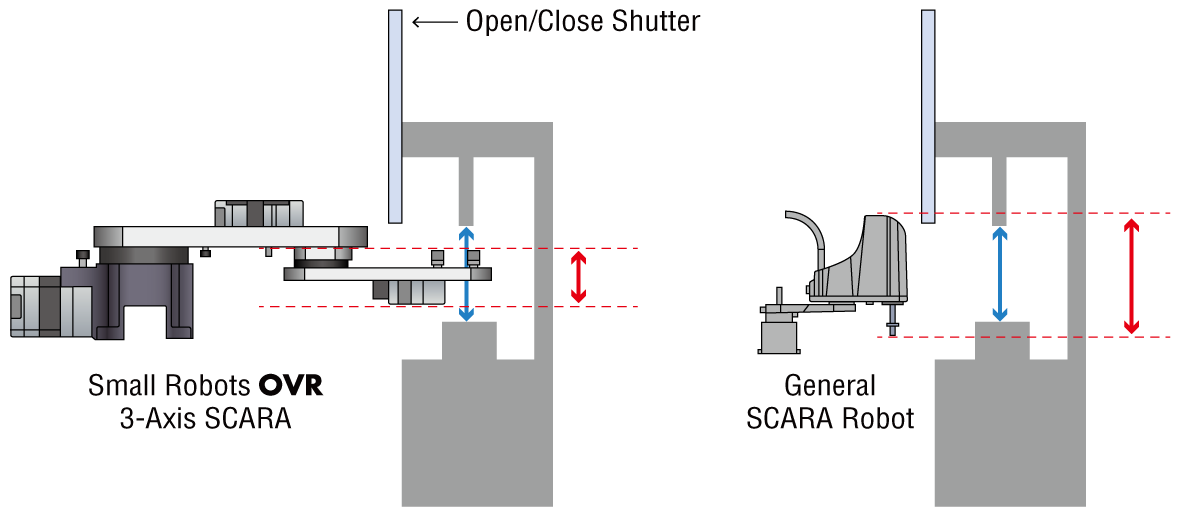

Flat SCARA Robot

Compared to general SCARA robots, the flat design allows the robot to handle narrow spaces, such as for attaching and detaching parts to and from equipment.

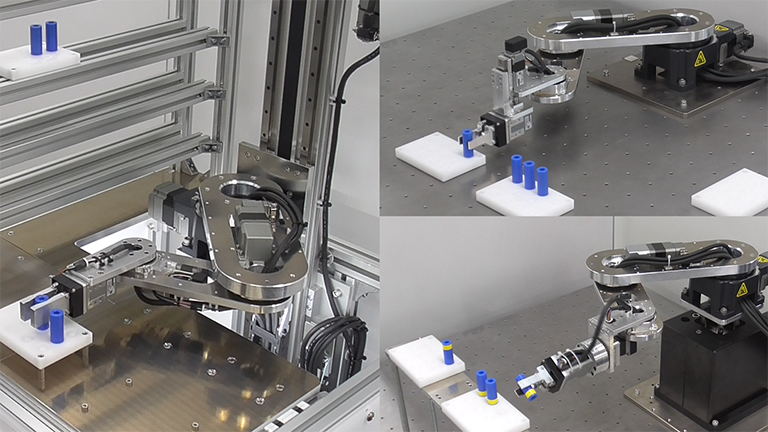

Customizable Design to Fit Your Equipment

This robot’s design can be freely customized according to the application.

- Flat and compact structure

- The 1st and 2nd arms are mounted, and the 3rd arm can be freely customized.

- It is lightweight at 7.6 kg. The movable range is expanded horizontally as well as vertically by mounting it on an actuator.

We offer convenient accessories to facilitate quick robot installation.

Easy-to-Control Robot Controller

MRC01 is a robot controller that can control robots equipped with the AZ Series.

The programming software MRC Studio (free of charge) is so simple that even those inexperienced in controlling robots can master it quickly.

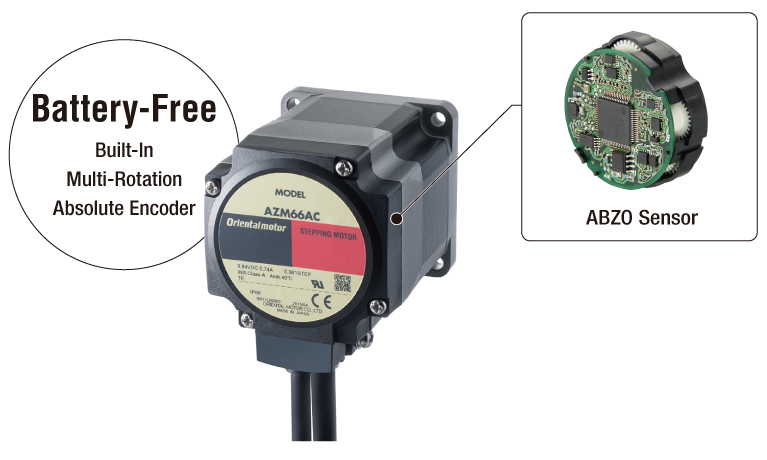

Using AZ Series With Battery-Free Built-In Absolute Encoder

All axes use the αSTEP AZ Series (DC input).

Absolute mode eliminates the need for external sensors, reduces wiring, and reduces maintenance by eliminating the need for battery management.

DC input allows easy power line routing. Installation and layout changes to the line can be adapted to flexibly.

Useful Tools Before Installing Robots

MRC Studio Simulator

This software (free of charge) enables simulation of actual movements on a PC at the stage of considering the introduction of a robot, without the robot itself or MRC01.

Click here for detailsMRC Reality

Virtual robots can be set up in real space to simulate operations.

Apps are available for smartphones/tablets and for head-mounted displays (Meta Quest 3).

Specifications

| Product Name | OVR3041K3-H | |

|---|---|---|

| Number of Axes | 3-Axis | |

| Input Voltage | 24 VDC | |

| Arm Length | 1st Arm | 230 mm |

| 2nd Arm | 180 mm | |

| Payload | 3 kg | |

| Movable Range*1 | 1st Axis | ±170 deg |

| 2nd Axis | ±140 deg | |

| maximum speed | 1st Axis | 300 deg/s |

| 2nd Axis | 300 deg/s | |

| 3rd Axis | 720 deg/s | |

| Composite (TCP)*2 | 1000 mm/s | |

| Repetitive Positioning Accuracy*3 | ±0.03 mm | |

| Permissible Inertia | 0.026 kgm2 | |

| Body Mass | 7.6 kg | |

| Installation Type | Floor Mount/Ceiling Mount | |

| List Price | Please Contact us for More Information | |

- *1: This is the range of operation for an installation origin posture with the positioning pin in the origin pin hole.

- *2: This is the maximum speed when the payload is 1 kg. At 3 kg, it is 300 mm/s.

- *3: Based on the specification values of each axis reducer.

- *Recommended power supply capacity is 24 VDC 170 W

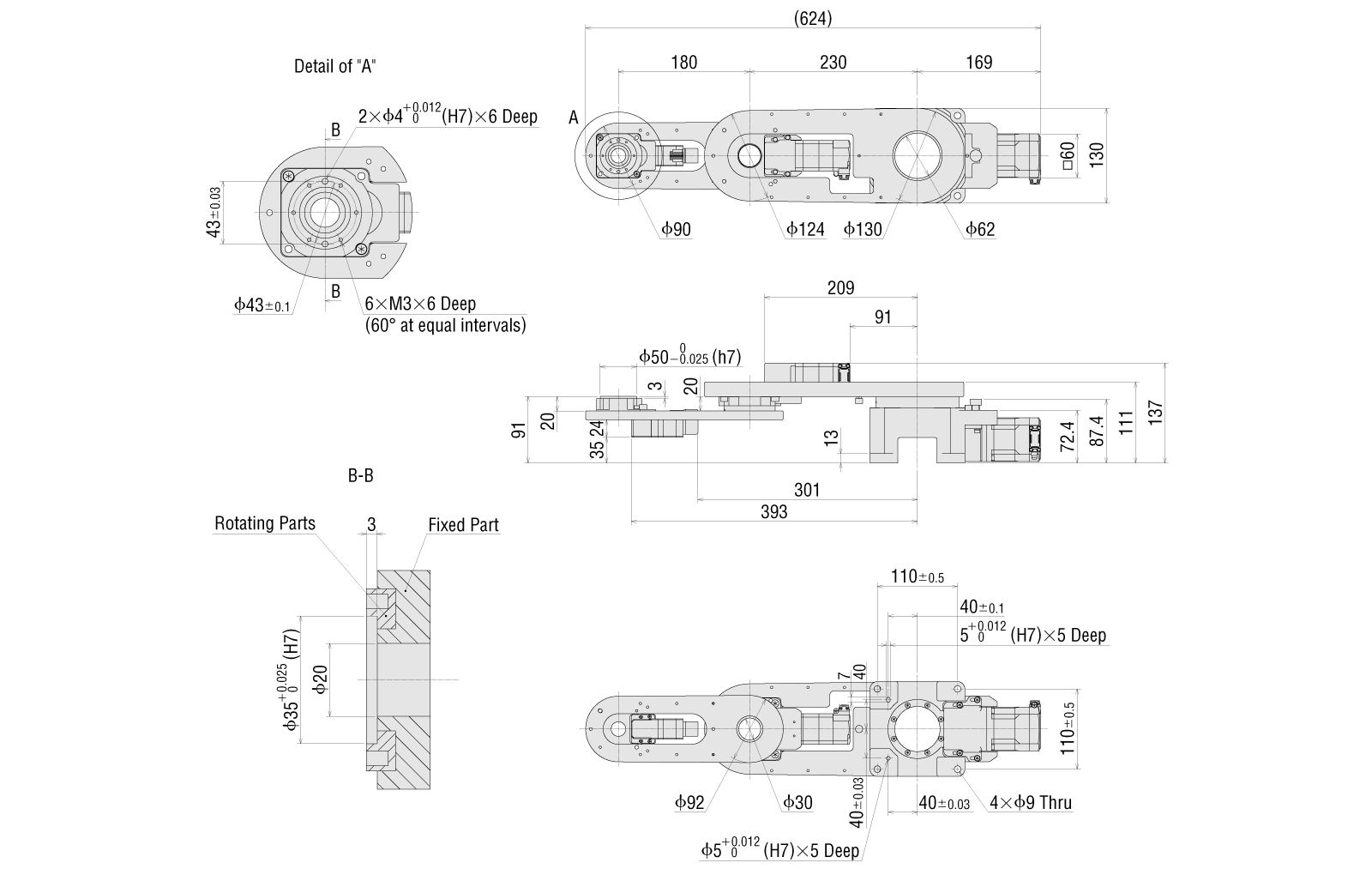

Dimensions/Motion Range Diagram

Dimensions (Unit = mm)

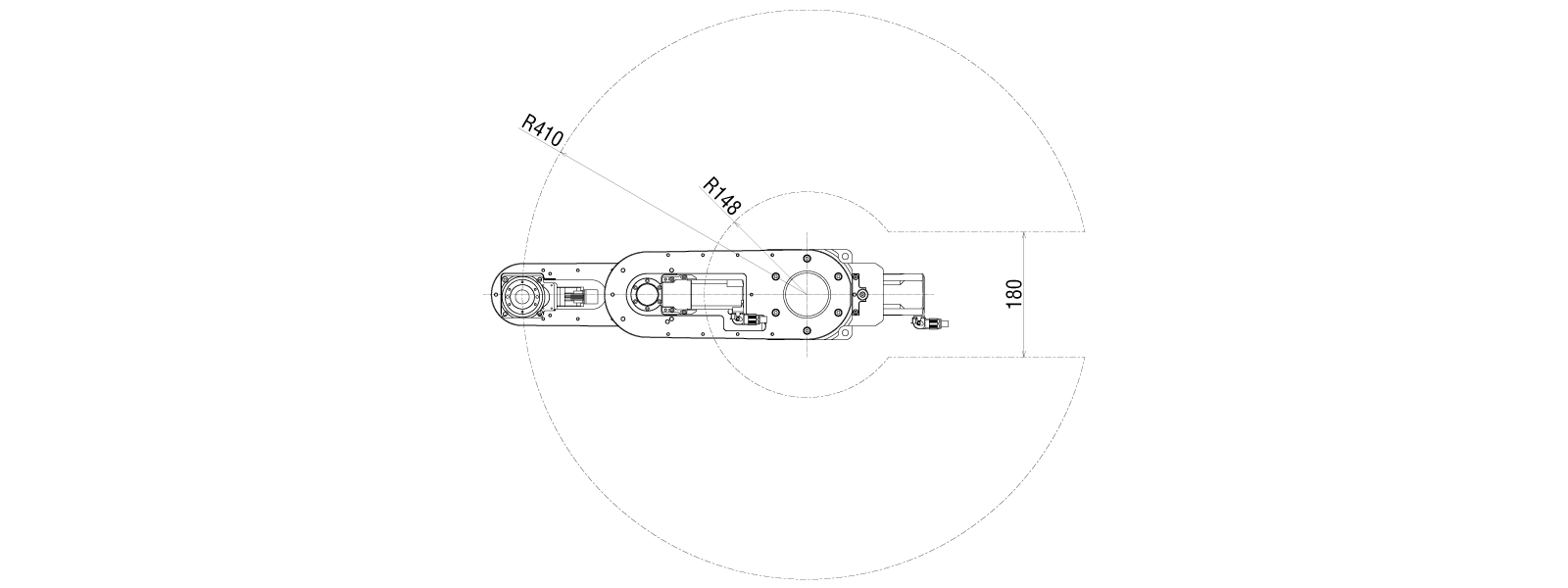

Motion Range Diagram (Unit = mm)

- *The maximum reach is 410 mm, but considering the singularity when using a robot controller, we recommend using it within 400 mm.

Various Data

| Technical Reference | 3-Axis SCARA (Technical Reference) |

|---|---|

| 3DCAD | OVR3041K3-H |

| 2DCAD | OVR3041K3-H |

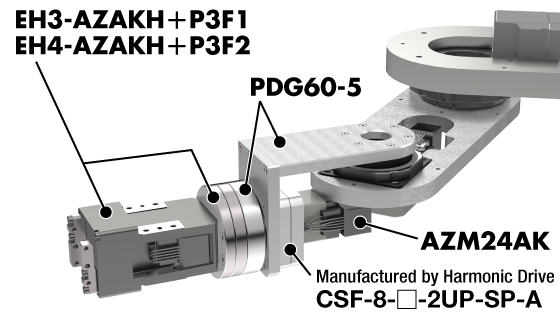

System Configuration

Robots, robot controllers, drivers, and cables must be ordered separately.

The robot can be easily controlled by using the robot controller MRC01 and the programming software MRC Studio.

The recommended drivers that can be connected to MRC01 are the DC input type driver AZD-KD or the mini Driver AZD-KR2D.

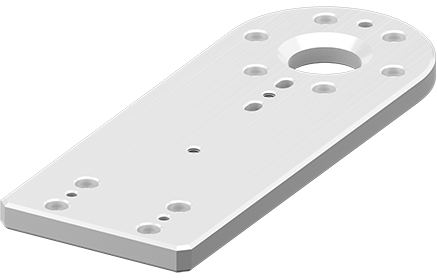

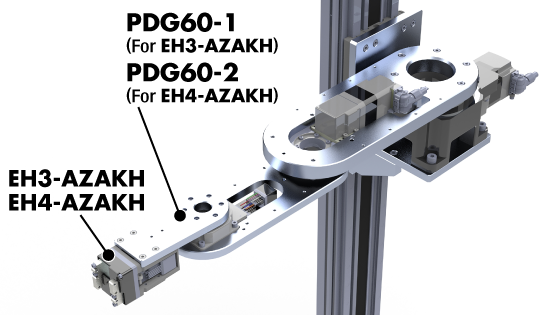

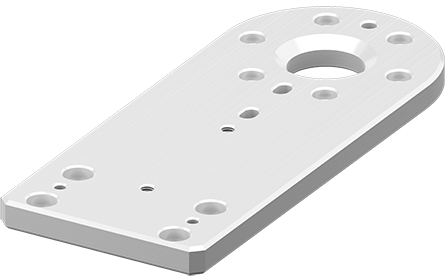

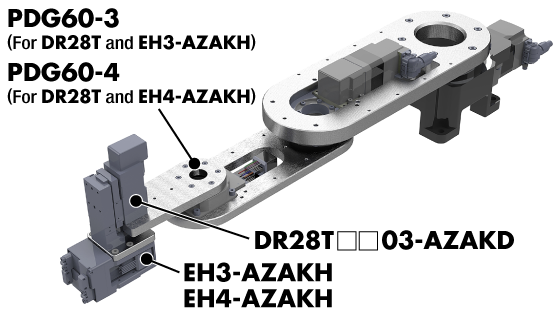

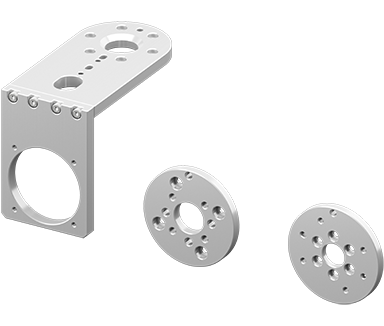

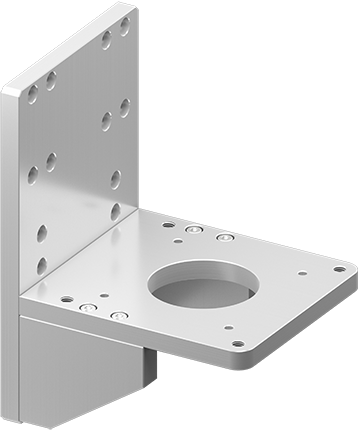

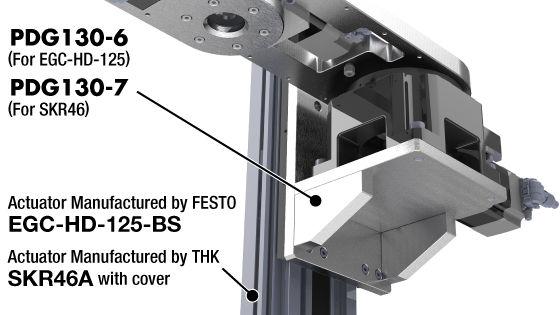

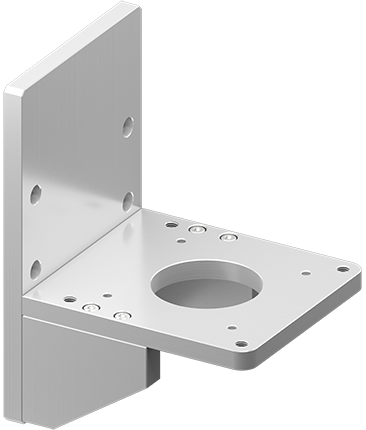

Mounting Bracket for 3-Axis SCARA

There are various mounting brackets that can be used for the 3-axis SCARA OVR3041K3-H.

| Product Name | List Price | Installation Image | Mass [kg] |

Dimensions | 2DCAD | 3DCAD |

|---|---|---|---|---|---|---|

|

PDG60-1

|

contact for information |  |

0.18 | PDG60-1 | PDG60-1 | PDG60-1 |

|

PDG60-2

|

contact for information | 0.16 | PDG60-2 | PDG60-2 | PDG60-2 | |

|

PDG60-3 |

contact for information |  |

0.20 | PDG60-3-1 PDG60-34 |

PDG60-3-1 PDG60-34 |

PDG60-3-1 PDG60-34 |

|

PDG60-4 |

contact for information | 0.18 | PDG60-4-1 PDG60-34 |

PDG60-4-1 PDG60-34 |

PDG60-4-1 PDG60-34 |

|

|

PDG60-5

|

contact for information |  |

0.27 | PDG60-5 PDG60-5-1 |

PDG60-5 PDG60-5-1 |

PDG60-5 PDG60-5-1 |

|

PDG130-6

|

contact for information |  |

1.6 | PDG130-6 | PDG130-6 | PDG130-6 |

|

PDG130-7

|

contact for information | 1.6 | PDG130-7 | PDG130-7 | PDG130-7 |