Small Robots OVR

5-Axis Articulated Robot

- Compact and Lightweight, Enabling Horizontal Movement in Combination With Electric Linear Slides

- Body Mass 12.5 kg

- Maximum Reach (horizontal) 350 mm, Payload 1 kg

- Drive Motor: AZ Series with battery-free built-in absolute encoder (DC input)

Tính năng |5-Axis Articulated Robot

Compact and Lightweight Design

The body mass is only 12.5 kg, with an installation area of 130 x 130 mm. The small size and light weight make it easy to transport and install. It can also be used in combination with electric linear slides to expand the horizontal operating range.

The Motor Can be Replaced by the Customer

Some of the motors can be replaced by the customer. Reduces the maintenance load (cost and time) after installation.

- *We will also replace the motors during maintenance and servicing. Please contact your nearest Oriental Motor branch or sales office.

Easy-to-Control Robot Controller

MRC01 is a robot controller that can control robots equipped with the AZ Series.

The programming software MRC Studio (free of charge) is so simple that even those inexperienced in controlling robots can master it quickly.

- Note: When using the robot, please consider its safety as an industrial robot. (Cannot be used as a collaborative robot)

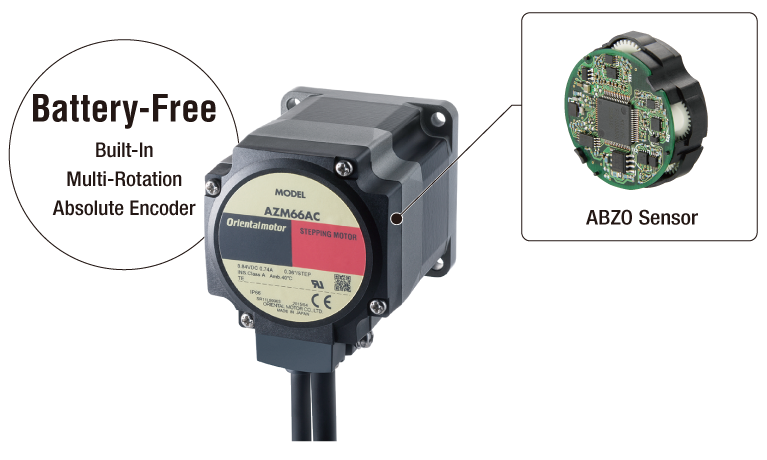

Using AZ Series With Battery-Free Built-In Absolute Encoder

All axes use the αSTEP AZ Series (DC input).

Absolute mode eliminates the need for external sensors, reduces wiring, and reduces maintenance by eliminating the need for battery management.

DC input allows easy power supply line routing. Installation and layout changes to the line can be adapted to flexibly.

Useful Tools Before Installing Robots

MRC Studio Simulator

This software (free of charge) enables simulation of actual movements on a PC at the stage of considering the introduction of a robot, without the robot itself or MRC01.

Click here for detailsMRC Reality

Virtual robots can be set up in real space to simulate operations.

Apps are available for smartphones/tablets and for head-mounted displays (Meta Quest 3).

Specifications

| Product Name | OVR5035K1-V | |

|---|---|---|

| Number of Axes | 5-axis | |

| Input Voltage | 24 VDC | |

| Maximum Reach | Vertical | 631 mm (upward) |

| Horizontal | 350 mm (downward) | |

| Payload | 1 kg | |

| Standard Cycle Time*1 | 0.9 sec. | |

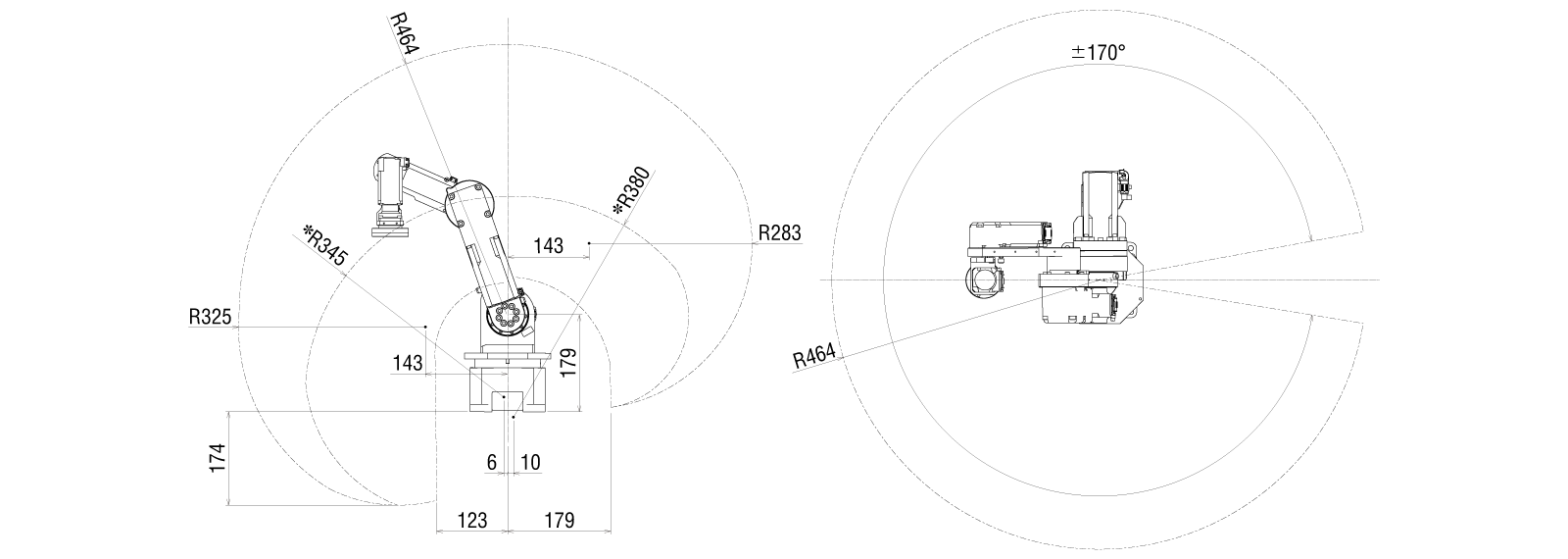

| Movable Range*2 | S-axis (rotation) | ±170 deg. |

| L-axis (lower arm) | −55∼+105 deg. | |

| U-axis (upper arm) | −115∼+145 deg. | |

| Bp-axis (wrist bending) | −90∼+125 deg. | |

| R-axis (wrist rotation) | ± 180 deg.*3 | |

| Repetitive Positioning Accuracy*4 | ± 0.05 mm | |

| Permissible Inertia (wrist rotation axis) | 0.0134 kgm² | |

| Body Mass | 12.5 kg | |

| Installation Type | Floor mount | |

- *1: The time required to move back and forth between 2 points, 25 mm high and 300 mm wide, with a 1 kg load.

Cycle time when the MRC01 robot controller is used. - *2: This is the range of operation for an installation origin posture (L-, U-, Bp-axis vertical positioning) with the positioning pin in the origin pin hole.

- *3: ± 170 deg. when using the MRC01 robot controller.

- *4: Based on the specification values of each axis reducer.

- *Recommended power supply capacity is 24 VDC 600 W

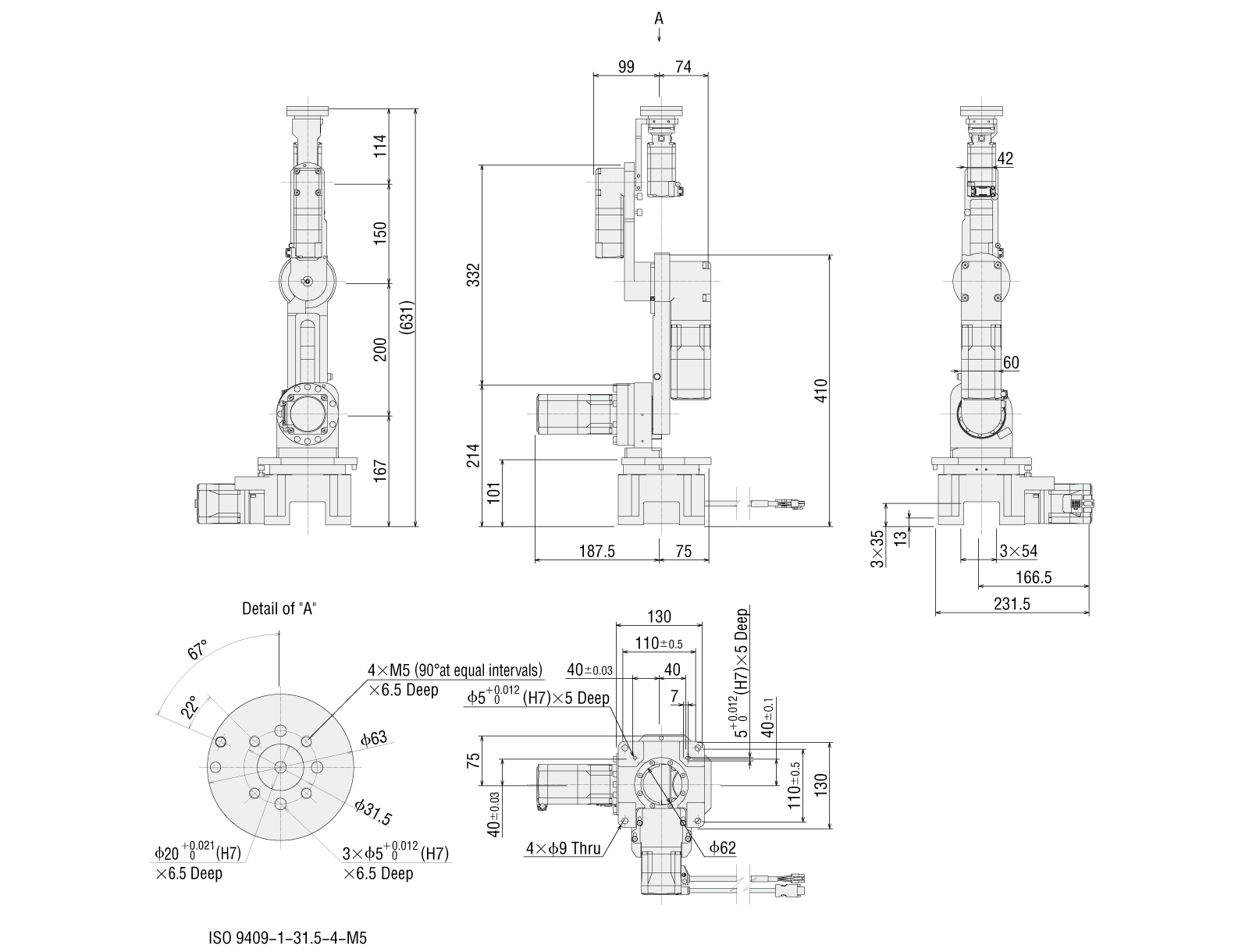

Dimensions/Motion Range Diagram

Dimensions (Unit: mm)

Motion Range Diagram (Unit: mm)

- * The range within which the end effector can operate when it is facing down.

Various Data

| Technical Reference | 5-Axis Articulated |

|---|---|

| 3DCAD | R004.zip |

| 2DCAD | R004.dxf |

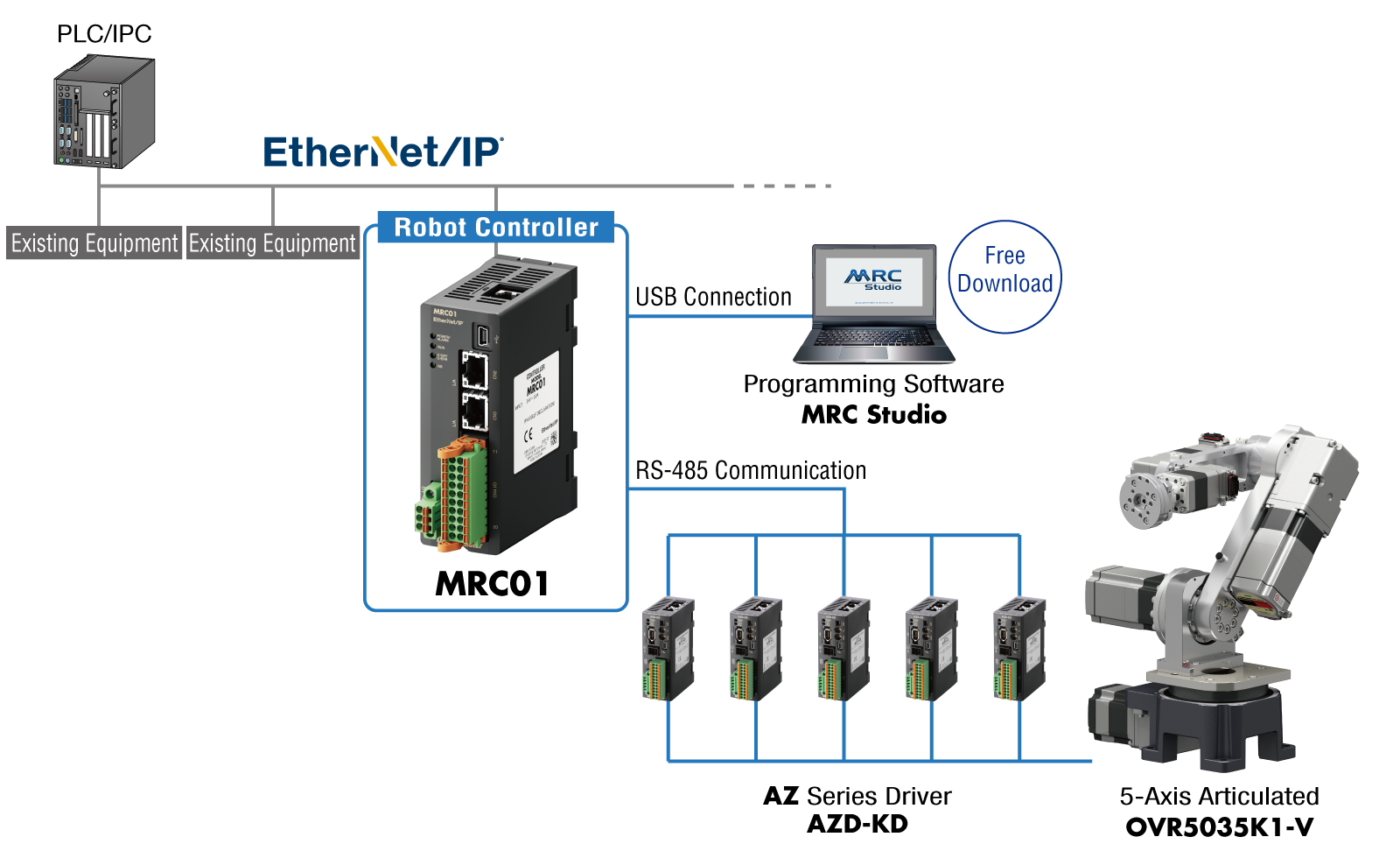

System Configuration

Robots, robot controllers, drivers, and cables must be ordered separately.

The robot can be easily controlled by using the robot controller MRC01 and the programming software MRC Studio.

The recommended drivers that can be connected to MRC01 are the DC input type driver AZD-KD or the mini Driver AZD-KR2D.