AC Motors

Motors capable of constant speed, instantaneous bi-directional operation, load holding during vertical operation, speed control, and tension control are available. Our motors can accommodate the various movements required by the customer’s equipment. We also offer motors that can be operated in harsh environments, such as watertight, dust-resistant, and safety-enhanced explosion-proof motors.

AC Motors

Tổng quan và thông tin liên quan

Overview of AC Motors

AC motors are widely used as a power source for automated equipment because they can be operated easily by simply connecting the motors to an AC power supply.

Oriental Motor offers AC motors incorporating various operation functions. These can also be combined with circuit products for brake packs and speed control, or assembled with actuator products such as gearheads and linear heads. Therefore, these can be used in a wide range of applications.

Features of AC Motors

Motors for Easy Operation

AC motors include single-phase motors used with a single-phase power supply and three-phase motors used with a three-phase power supply.

Single-Phase motors can be operated by connecting them to a single-phase power supply via the included capacitor.

Three-Phase motors do not require a capacitor and can be operated by connecting them directly to a three-phase power supply.

Refer to here for a concept video and PDF of the connection.

Rotation Speed Determined by Power Supply Frequency

The basic speed (synchronous speed*) of an AC motor is determined by the power supply frequency and the number of poles.

Since most of Oriental Motor’s products are 4-pole, the synchronous speed is as follows.

- 50 Hz

- 1500 r/min

- 60 Hz

- 1800 r/min

The actual rotation speed varies with load torque.

When a load torque equivalent to the rated torque is applied, the rotation speed of Oriental Motor’s products will be approximately as follows.

- 50 Hz

- 1200~1300 r/min

- 60 Hz

- 1450~1600 r/min

The rated speed of our AC motors is set within these ranges for each product.

When calculating the speed of the device in more detail, refer to this rated speed.

Also, the power supply frequency may vary by region. For automatic devices that will be used in various regions, use different gearhead gear ratios.

Select the Motor According to Load Torque

The torque generated by each AC motor is different depending on the motor frame size and length.

Oriental Motor has systematized motor sizes and output power, and offers products with frame sizes ranging from 42 mm to 104 mm and output power from 1 W to 200 W.

Depending on the load torque, you can choose a motor from a wide range of variations.

Overview of AC Speed Control Motors

An AC speed control motor is a motor that combines an induction motor or reversible motor with a tachogenerator (AC generator) for speed detection. You can change the speed by using it in combination with a dedicated control circuit (speed controller).

A wide-ranging product line is available, and these products can be easily used like AC motors.

System Configuration

This system is driven by a combination of a motor that incorporates a tachogenerator (AC generator) to detect speed and a speed controller (control circuit).

Set the rotation speed of the motor by using a speed potentiometer, external DC voltage, or similar.

Structure

AC speed control motors have a tachogenerator (AC generator) built into the rear of the motor.

The feedback signal from the tachogenerator and the setting speed are compared by the speed controller to adjust the motor rotation speed.

Control Block Diagram

The speed control unit of the speed controller compares the speed feedback signal from the tachogenerator built into the motor with the speed command signal set by a speed potentiometer, etc.

The result of this comparison is then sent to the voltage control circuit. The voltage control circuit adjusts the voltage applied to the motor and controls the motor rotation speed.

Speed - Torque Characteristics

With AC speed control motors, rated operation* is possible if operation is in the range below the safe-operation line (①) shown in the figure below.

When the load torque changes relative to the set rotation speed, the speed also changes. The change in speed for each setting speed is indicated by the vertical line (②) in the characteristics diagram.

- *Induction motors have a continuous rating and reversible motors have a 30 minutes rating.

Features of AC Speed Control Motors

A Wide Range of Products to Choose From to Suit Your Usage

The US2 Series and the DSC Series have digital setting and display features.

With the US2 Series, speed can be changed easily just by connecting to a power supply and performing adjustment with a potentiometer.

You can choose the one that best suits your usage.

Simple Functions That are Easy to Use

AC motors have won extensive loyalty for many years for their performance and quality as well as ease of use. AC speed control motors maintain this performance, quality, and user-friendliness, while providing the functions necessary for speed control motor operation. This is a speed control motor that can be easily used like an AC motor.

Use of a High Permissible Torque, High Strength Gearhead

The KII Series motor and gearhead that offer higher permissible torque and strength are used.

Special side panels in the gearhead have increased case rigidity, and heat processing (carburization) has increased the strength of the gears.

Related Information

For Those Who Have Not Decided on a Series

View More About the Selection Guide

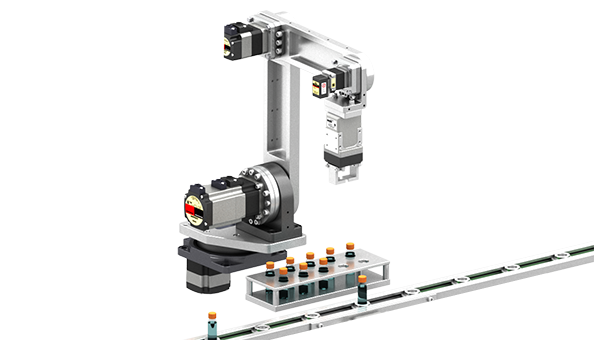

Selection Guide

This selection guide will help you find the product series best suited for your equipment. Select an equipment application example and follow the guidance to select a product series.

Learn More

View More about the Problem Solving Case Studies

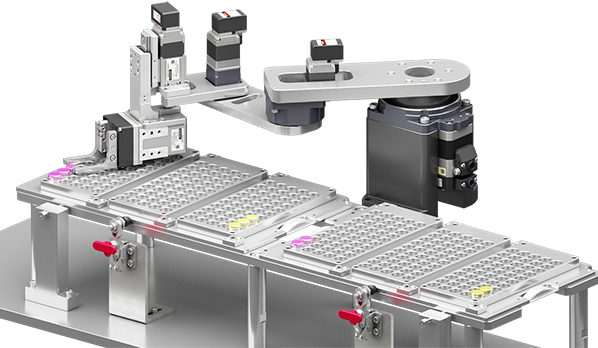

Problem Solving Case Studies

Here is the information on the solutions for your equipment issues. We introduce examples of in-house production of equipment used in actual manufacturing sites, as well as application examples of our recommended products to solve the issues with conventional equipment.

Learn More