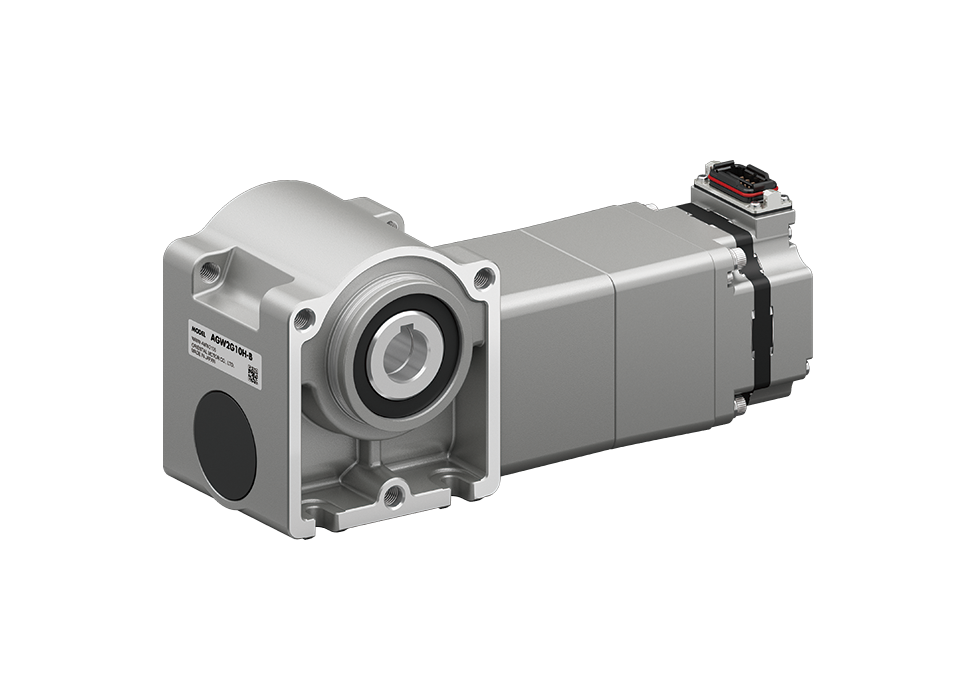

Worm Gearhead

- Applicable Motor: Brushless motor, parallel shaft gearhead, 30 W

- Permissible torque is approximately 3 times that of parallel shaft gearheads

- For load holding applications that require self locking to prevent collapsing under its own weight

- Space saving with right-angle shaft/hollow shaft

Tính năng |Worm Gearheads

Significantly Increased Permissible Torque

Despite its compact size and low clearance, the gear is capable of increasing permissible torque by approximately 3 times compared to a parallel shaft gearhead.

It is recommended for the following applications.

- When high torque is required with high deceleration and low speed drive

- When you require a more compact mechanism (lower clearance)

Example: BLE2 Series 30 W motor + parallel shaft gearhead (GFV gearhead) combined with worm gearhead

Self Locking Load Retention

Self locking* is when the worm gear becomes stuck due to friction when it is rotated from the side of the output shaft (the worm wheel side).

This improves safety when used in applications that require protection against falling due to its own weight (e.g., lifting and lowering drives, reversing drives, etc.).

- *Self locking may not be effective depending on lubrication, tooth surface condition, impact, and vibration.

-

Structure -

Inclined Conveyor (Lift drive) -

Reversing Device (Reverse drive)

Differences From Electromagnetic Brakes

Our electromagnetic brakes are designed to continue holding the load when the power is turned off. (Power off activated type electromagnetic brake)

Unlike electromagnetic brakes, self locking is suitable for mechanisms that do not like reverse operation during rotation as well as holding force at standstill.

Control and wiring of the electromagnetic brake is not required, simplifying the equipment setup.

Space Saving With Right-Angle Shaft/Hollow Shaft

- Placement of the output shaft at a right angle to the motor shaft

- Hollow shafts allow for direct connection to the drive shaft, reducing the number of parts such as couplings and belt pulleys

- Flange mounting/foot mounting is possible, allowing for greater freedom in the mounting design

Product Line

| Product Name | Gear Ratio | |

|---|---|---|

|

AGW2G10H-B | 10 |

| AGW2G20H-B | 20 |

Applicable Products

- *The motor, gearhead, and worm gearhead are all sold separately.

| Motor | Parallel Shaft Gearhead | Worm gearhead | Gear ratio of the output shaft when combined | ||||

|---|---|---|---|---|---|---|---|

| Model | Series | Output Power | Product Name | Gear Ratio | Product Name | Gear Ratio | |

| Brushless Motors | BMU Series BLE2 Series |

30 W | GFV2G□ GFV2G□S |

5, 10, 15, 20, 30 |

AGW2G10H-B | 10 | 50, 100, 150, 200, 300 |

| 5, 10, 15, 20 |

AGW2G20H-B | 20 | 100, 200, 300, 400 |

||||

| BXII Series BLH Series |

30 W | GFS2G□ | 5, 10, 15, 20, 30 |

AGW2G10H-B | 10 | 50, 100, 150, 200, 300 |

|

| 5, 10, 15, 20 |

AGW2G20H-B | 20 | 100, 200, 300, 400 |

||||

- A number indicating the gear ratio is specified where the box □ is located in the product name.

Introduction of Applicable Motors

Brushless Motors

BMU Series

- Easy "rotate-and-push" operation

- 4-speed operation

- Easy wiring

- 30~400 W, 80~4000 r/min

Brushless Motors

BLE2 Series

- Multifunctional model with 4 selectable data setting methods

- Torque limited, 16-speed operation

- For the type with an electromagnetic brake, it can hold the load during vertical operation

- 30~400 W, 80~4000 r/min

Brushless Motors

BXII Series

- Multifunctional model capable of position control

- Speed regulation ±0.05 %

- For the Type With an Electromagnetic Brake, It Can Hold the Load During Vertical Operation

- 30~400 W, (2) 30~4000 r/min

Brushless Motors

BLH Series

- 24 VDC input, compact driver

- Ideal for incorporating in equipment

- RS-485 communication compatible

- 15~100 W, (80) 100~3000 r/min