Case Study of the Downsizing of Dispensers (Filling Equipment)

Issue

Reducing Equipment Size

Conventional Equipment

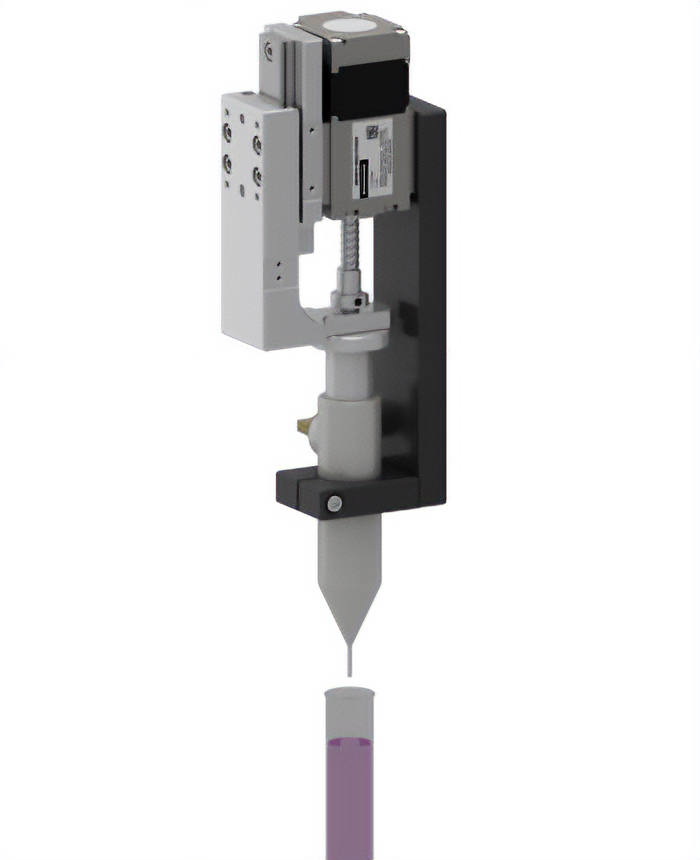

A piece of equipment with a self-made mechanism that uses a stepper motor and ball screw to apply a constant and highly accurate amount of liquid.

- Application

- Dispensing solutions, paints, adhesives, etc.

Conventional Problems

- There is limited installation space for the application nozzle, and the self-made mechanism can no longer be accommodated

Solution

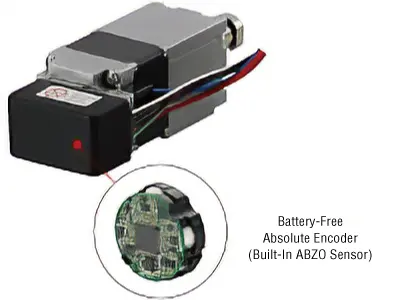

Compact Electric Cylinder DR Series

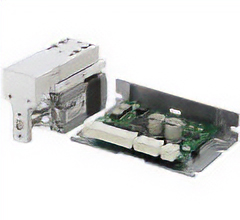

Integrated Motor and Ball Screw for Space Saving

The use of the compact electric cylinder DR Series, which integrates a stepper motor and ball screw, allows the overall length of the equipment to be designed shorter than with a self-made mechanism.

Specific Application Examples

28 mm Frame Size Compact Body

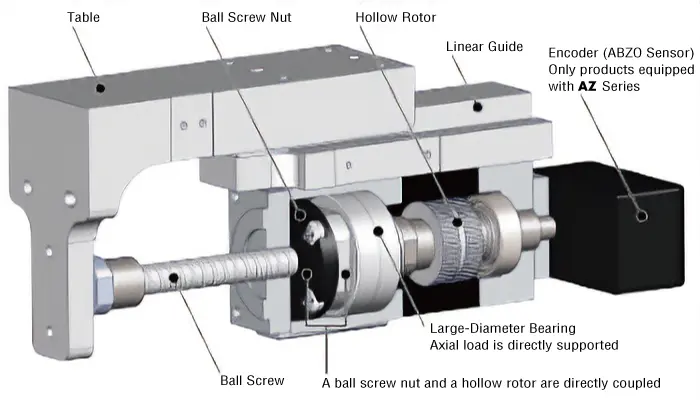

Integrates a hollow rotor and ball screw nut, and features a structure that houses the ball screw in the motor section, making the product itself extremely compact.

- *The above structural drawing is an example.

Omits Space Allocated for Connecting Parts

Since connecting parts such as linear guides and couplings are no longer necessary, the equipment as a whole can be made smaller.

[Configuration Examples of Cases where the Load is Driven by the Same Stroke]

| Configuration Number of Parts |

Configuration Image | Parts Used | |

|---|---|---|---|

| When Homemade | 9 Points |

|

① Mounting plate, ② Transfer table, ③ Linear guide, ④ Coupling, ⑤ Fixed side block, ⑥ Ball screw, ⑦ Fixed side bearing, ⑧ Support side block, ⑨ Support side bearing |

| When Using DR Series Table Type |

1 Point |

|

① Mounting plate |

Can be Installed According to the Installation Space

The DR Series offers a wide variety of mounting methods. You can select a mounting method that maximizes the use of limited installation space.

When multiple units are used, they can be mounted closely together. It also contributes to space saving in terms of equipment width.

[Mounting example for table type and rod type]

| Front Mounting | Side Mounting | Installation with Flange (Table type only) |

Mounting With a Foot Mounting Plate |

|---|---|---|---|

|

|

|

|

- *Material: Aluminum, Surface Treatment: None

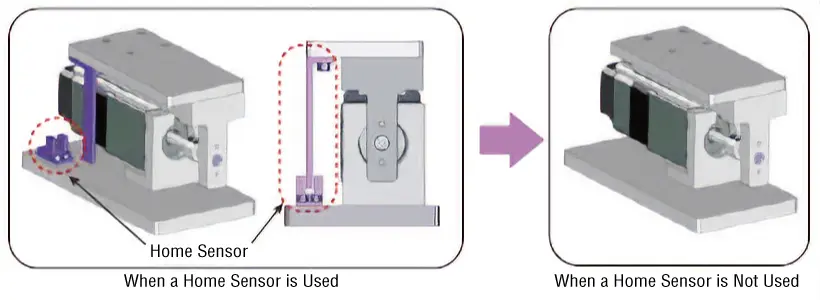

Eliminates Installation Space and Wiring for the Home Sensor

For αSTEP AZ Series Equipped Type*, position information is detected and managed by a mechanical absolute encoder, eliminating the need for a home sensor on the mechanism side. In addition to reducing the installation space for the sensor, sensor wiring can also be omitted.

- *The DR Series contains the αSTEP AZ Series-Equipped Type, and the PKP Series-Equipped Type. Please check the product page for details.