Case Study of High Flow Rate Pumping and Flow Adjustment

Issue

Increasing the Flow Rate

Conventional Equipment

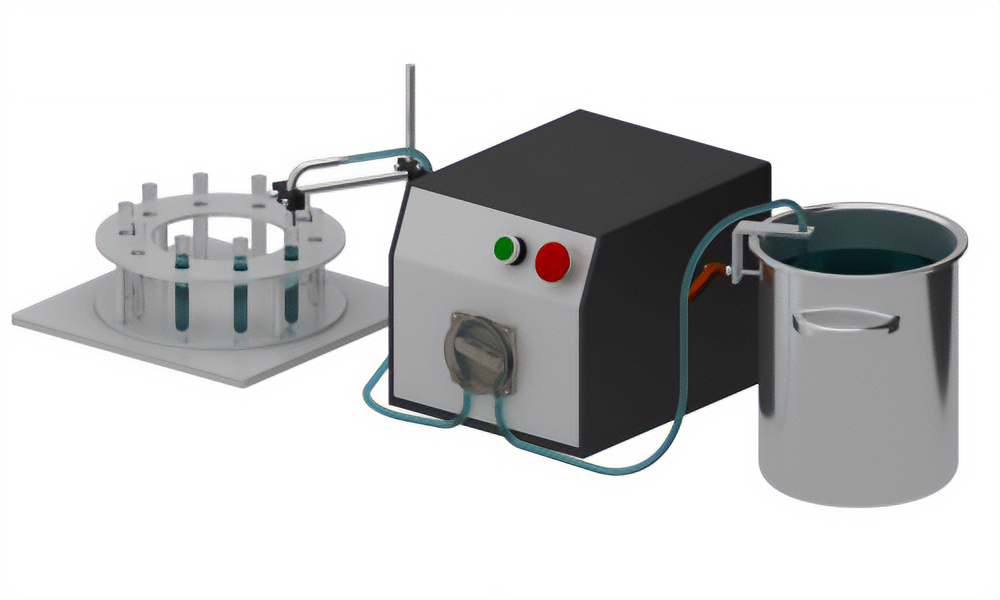

A piece of equipment that exhausts a constant and accurate amount of liquid using a stepper motor with DC input.

- Application

- Reagent Manufacturing

Conventional Problem

- I want to increase the speed to increase the feed amount, but there is insufficient torque

Solution

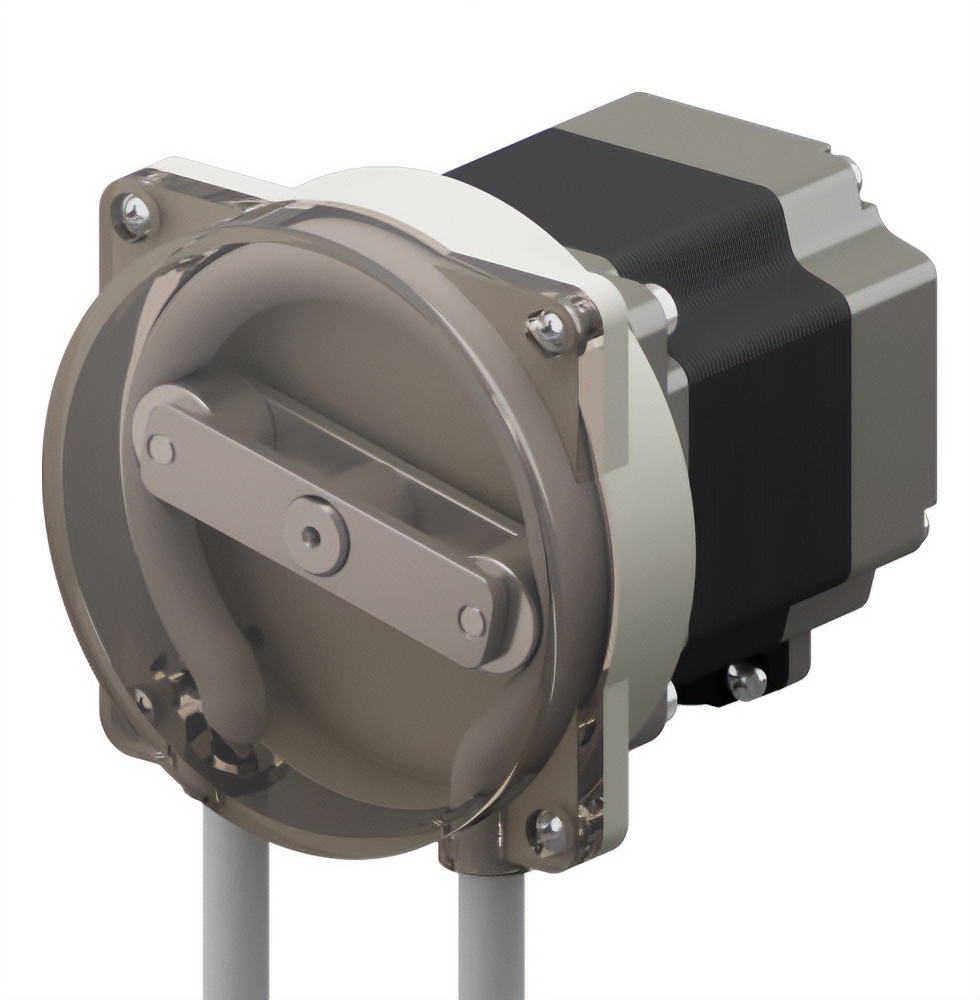

RKII Series stepper motor

Increased Torque at High Speeds and achieving a high Flow Rate

The AC input stepper motor RKII Series has superior torque characteristics in the high-speed range compared to DC input motors. As a result, the feed speed of the load can be increased while the size of the motor remains the same.

Specific Application Examples

Demonstrating Torque at High Speeds

AC input type stepper motors can carry the rated current even in the high speed range and have superior torque characteristics compared to DC power supply type.

Since motor torque and current value are proportional to each other, if you want to obtain high torque, you need to increase the current value as well.

In the RKII Series, the driver rectifies the AC power supply (100 VAC, 200 VAC) to 280 VDC and applies it to the motor.

By increasing the applied voltage, the rise of the current is sped up and the torque in the high-speed range is secured.

As with DC Input, Load Holding is Possible While Stopped

Since the AC power supply is rectified to DC and supplied to the motor, it has stable holding torque even when stopped and prevents backflow of liquid.

The value of holding torque at motor standstill can be adjusted by setting the driver's stop current.

Check Flow Rate with Encoder-Equipped Type

Using a motor with an encoder enables operations such as monitoring the present position and detecting position errors.

This contributes to improved equipment reliability by early detection of problems that may affect the load’s feed amount.