Case Study of Syringe Pump Dispensing Volume Accuracy Improvement

Issue

Improving the Accuracy of the Dispensing Volume

Conventional Equipment

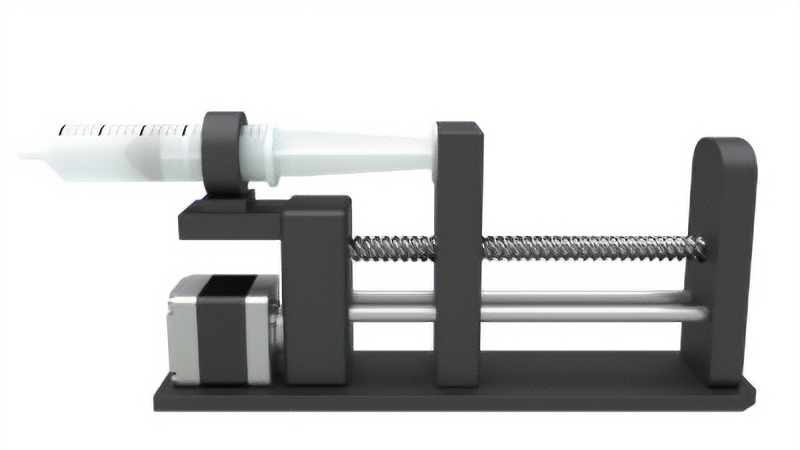

- Used in Applications That Dispense Liquids Such As Blood and Chemical Solutions

- Driven by 2-Phase Stepper Motors With a Basic Step Angle of 1.8˚ or 5-Phase Stepper Motors With a Basic Step Angle of 0.72˚, Combined With Ball Screws and Other Mechanisms

Conventional Problems

- The Amount of Liquid Dispensed May Vary

- Though It is Possible to Make Improvements by Changing the Mechanism, Avoiding Changing the Size of the Mechanism Part or Motor As Much as Possible is Desired

Solution

PKP Series High-Resolution Type

Resistant to Frictional Load and Realizes High-Precision Positioning

Contributes to Improved Accuracy of the Dispensing Volume

Stepper motor PKP Series high-resolution type is resistant to frictional load and realizes high-precision positioning. Contributes to improved accuracy of dispensing volume in syringe pumps, etc.

Specific Application Examples

Structure Resistant to Frictional Load

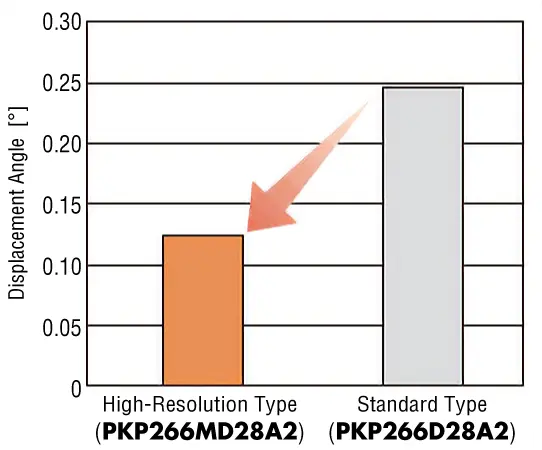

The high-resolution type is a motor with a basic step angle of 0.9˚ for 2-phase and 0.36˚ for 5-phase. Compared to the standard type, the rotor has twice as many teeth. Therefore, the displacement angle for frictional load can be reduced. The pump operates stably even in applications such as syringe pumps, which are constantly subjected to frictional loads, thereby improving the accuracy of the dispensing volume.

Watch the video for features and examples of use

Comparison of displacement angles due to frictional load (reference values)