Modular Automation Compatible Products

Solutions that liberalize automation

- Layout-Free Equipment

- Increased Productivity

- High-Mix Low-Volume Production

- Reduction of Manpower Shortage

- Space Saving

- Energy Saving

New Concept Proposal From Oriental Motor for the Future of Mobile Automation

To the new drivers of automation, which continue to evolve at an unprecedented speed. Battery-powered, compact, lightweight, and high-performance items built on world-standard technology unlock the idea of automation and make all possibilities a reality. It's a lineup that gives you endless ideas. Join us in creating the next generation of motion.

The Key to Flexibility is to Realize "Layout-Free" Automated Equipment and Lines.

These days, companies are required to have the flexibility to respond to changes in the external environment, such as manpower shortages, natural disasters, and responses to changes in world affairs. More and more workplaces are working on automation to replace manual labor for transporting workpieces, working in lines, and working in areas that are difficult to access. In addition, the number of companies that are working on modularization, in which line configurations can be reconfigured according to the situation, seems to be gradually increasing. The key to solving these issues is the realization of "layout-free" automated equipment and lines.

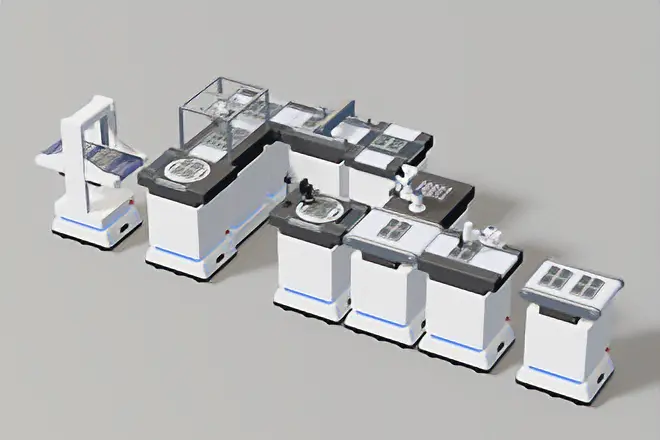

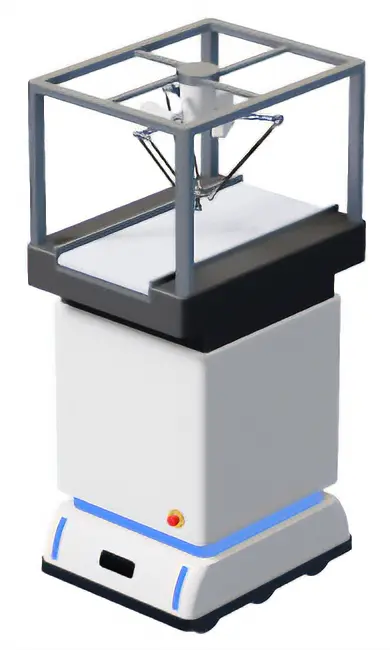

Example: Load transportation robot between processes

Conveyors that used to divide the line can be replaced by transportation robots, allowing for flexible transfer and aiming for a more efficient production line. A robot with a small footprint can move and work in a limited space. It is an effective means of replacing manual labor and increasing space efficiency.

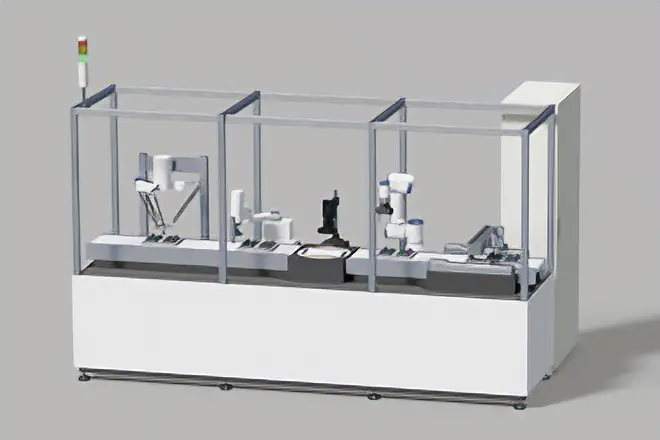

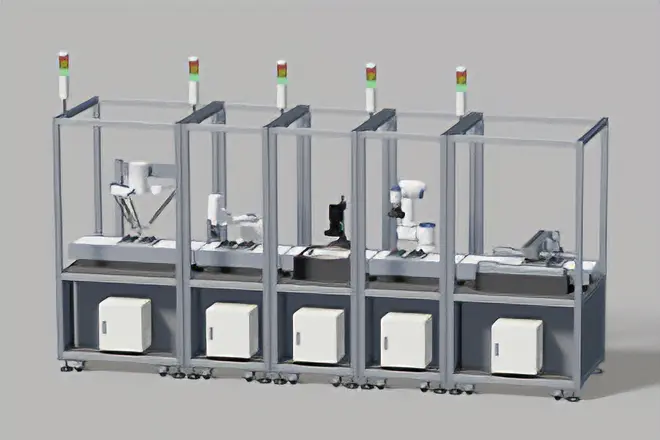

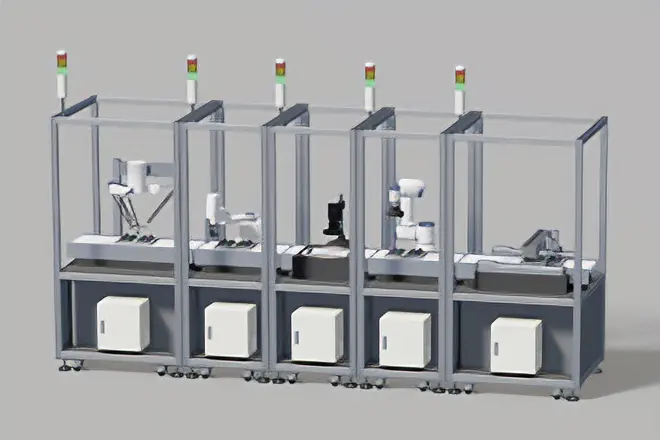

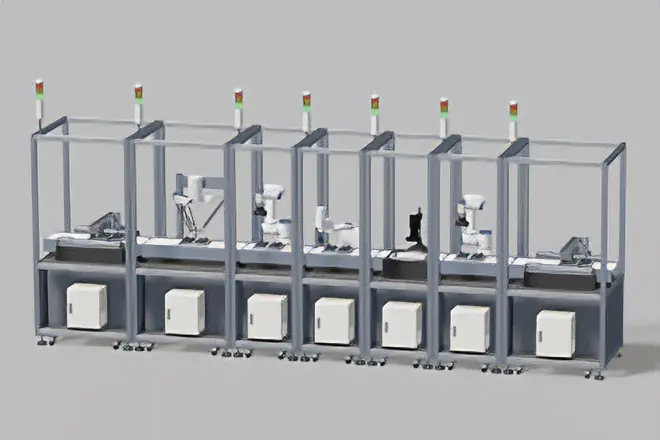

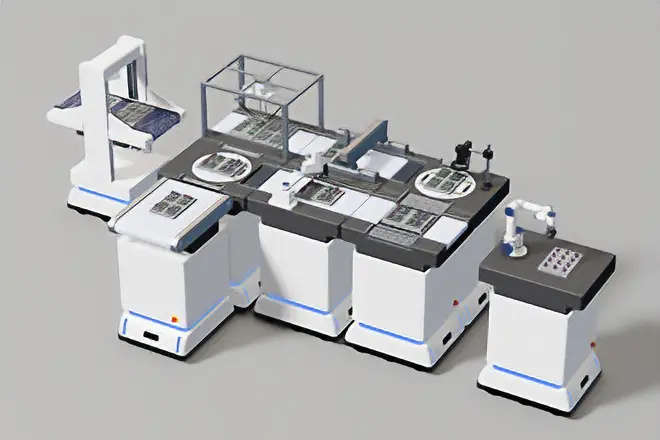

Example: Modular lines that can be flexibly reassembled to suit the product being produced

By modularizing the equipment by process, flexible layout changes can be expected in accordance with the products produced.

To achieve modularization, equipment must be standardized to a certain standard size and power wiring must be simplified.

Since it is assumed that the equipment is to be moved, lightweight and compact equipment should also be considered.

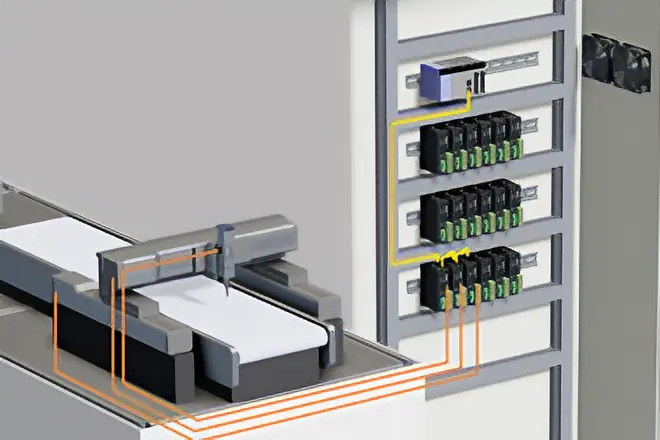

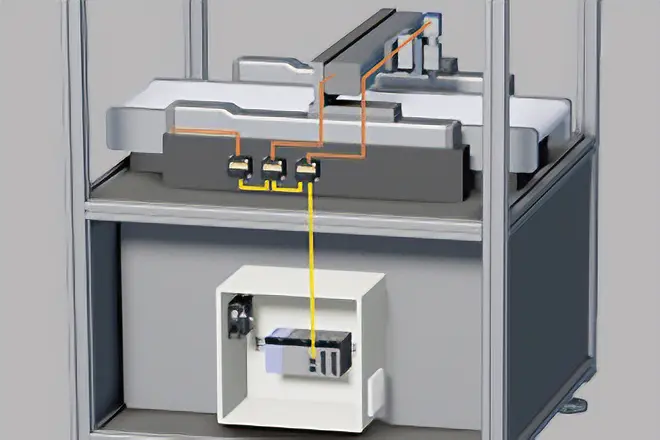

The αSTEP AZ series mini driver, a modular automation compatible product, is small and lightweight, allowing for decentralized placement of drivers.

It is possible to design smaller and lighter equipment by reducing switchboards and downsizing the distribution panel.

Flexible layout changes are possible according to the products produced.

In the near future, all production facilities will be battery-powered and self-driving, and AI will be used to make layout changes along efficient travel routes.

8 types 9 units

8 types 11 units (2 units added due to line change)

"Modular Automation Compatible Products" Equipped With the Elements Necessary to Realize "Layout-Free" Automated Equipment and Lines

?

- Automatic conveying without the use of fixed conveyors.

- The production line is composed of modular, lightweight, and compact equipment.

- Eliminate AC power supply routing and increase travel range.

Necessary elements for implementation:

Battery powered, DC input.

Lightweight and compact

?

Please consider Oriental Motor's Modular Automation Compatible Products.

What is a Modular Automation Compatible Product?

"Modular automation compatible products" are a group of products that share common concepts of being battery-powered, compact, and lightweight. Ideal for installation in self-propelled equipment and mobile facilities, it contributes to the realization of flexible automation lines and mobile automation, which will be increasingly demanded in the future.

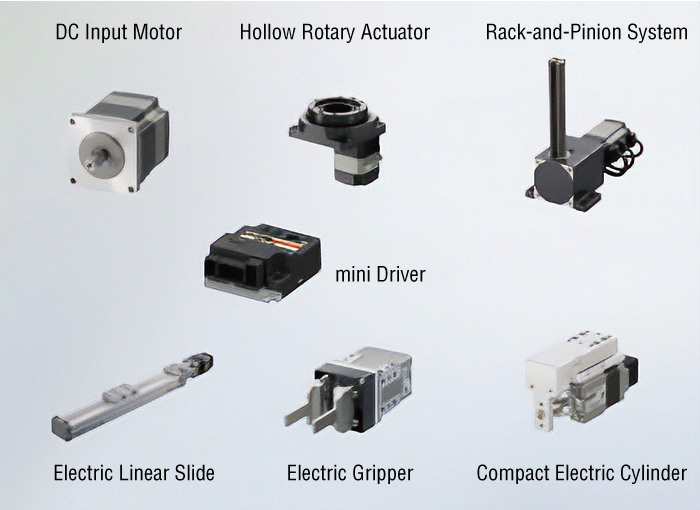

Modular Automation Compatible Products Lineup Introduction

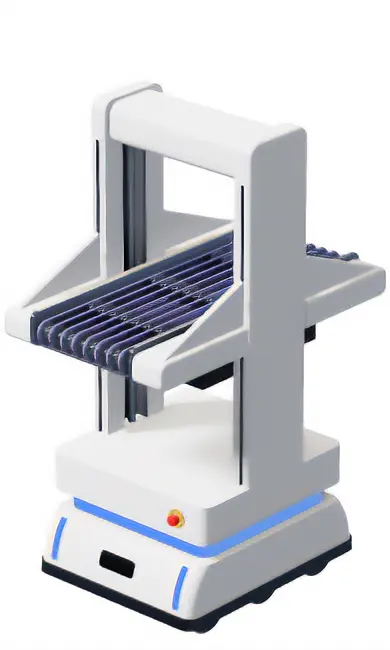

BLV Series R Type

It can be set to the low speed operation of just 1 r/min to achieve smooth drive. Both the motor and the driver are very small and light-weight. This helps in the development of even more compact battery drive devices.

αSTEP AZ Series mini Driver & Motor, Actuator

αSTEP, which employs Oriental Motor’s unique closed loop control, is equipped with an ABZO sensor. Absolute systems are now possible with no battery required. mini Driver is a compact and lightweight design for embedded applications and control cabinet space reduction. This driver can be connected to the Oriental Motor AZ Series DC input motors and electric actuators equipped with such motors. This contributes to the development of battery-powered equipment.

Product Application Examples

Here are some examples of the use of modular automation compatible product.

| Elevating and Lowering (Parts delivery) |

Parallel (Component mounted) |

X-Y-Z (Adhesive application) |

|---|---|---|

|

|

|

|

Elevating Equipment Roller Conveyor |

Each Joint Part Drive |

| Turntable (Visual inspection) |

Articulated (Machining parts mounted) |

Cross Roller Conveyor (Change in orientation of parts) |

|---|---|---|

|

|

|

|

Table Small 2-Row Conveyor in Table |

Each Joint Part Drive Hand Part Robot Controller |

Cross Conveyor |

| SCARA (Screw tightening) |

Conveyor (Component mounted) |

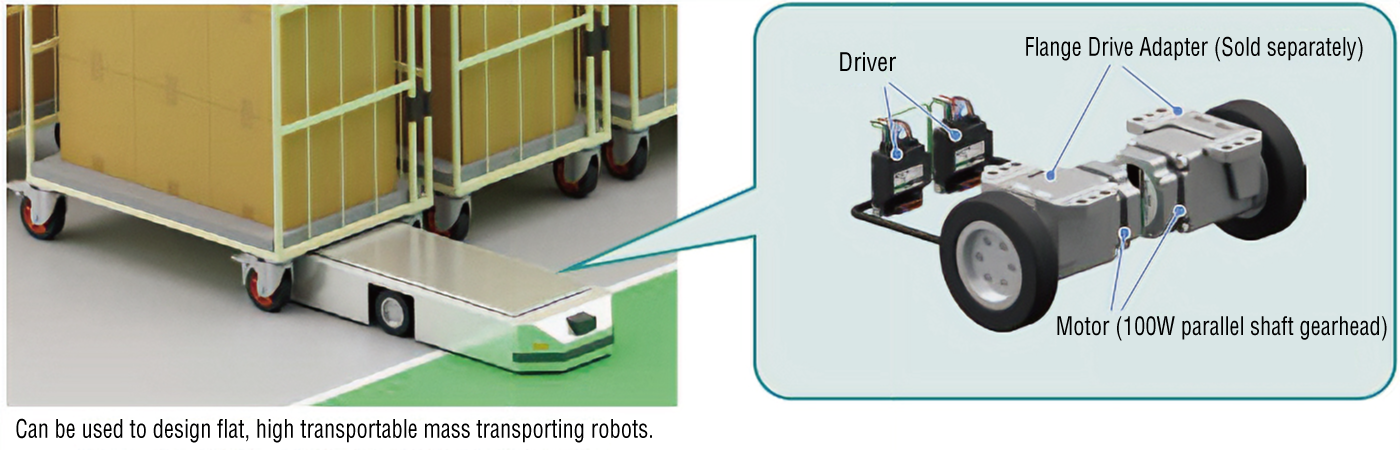

Transportation Robot (Wheel drive) |

|---|---|---|

|

|

|

|

Each Joint Part Drive Screw Tightening Section |

Conveyor |

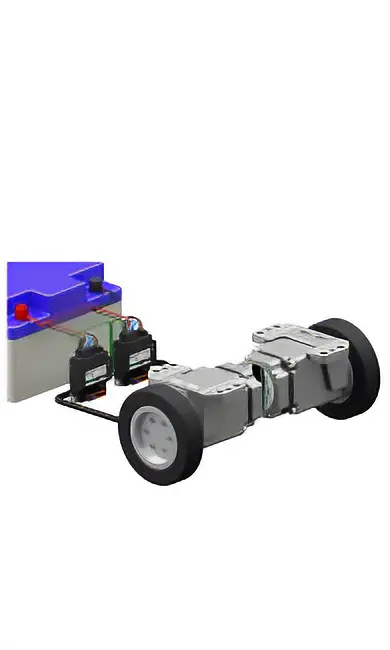

Wheel Drive |

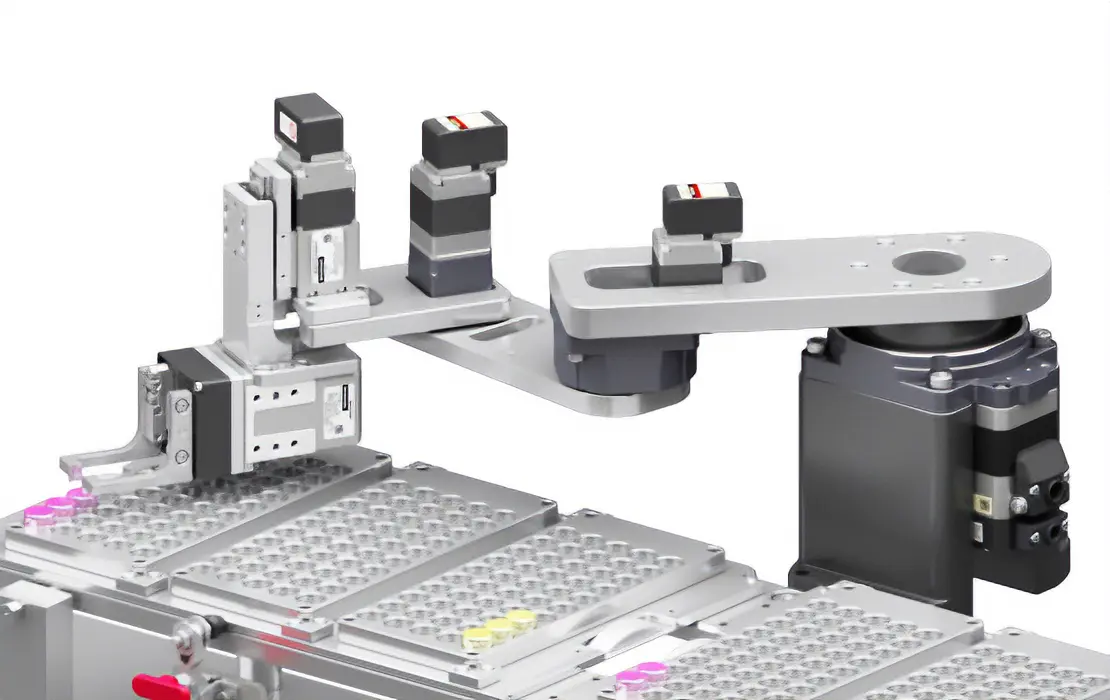

Examples of In-House Production of Equipment

Here are some examples of equipment that Oriental Motor has manufactured in-house. All of these are used in actual manufacturing sites. In addition to the structure and system configuration of the equipment, important points for product selection in each axis are explained. In addition, Oriental Motor provide support from equipment design to start-up.

Modular Automation Compatible Products

Brushless Motor BLV Series R Type

A brushless motor with DC input that achieves high power and compact size.

This helps in the development of even more compact battery drive devices.

Output Power: 100 W, 200 W

Speed Control Range: 1~4000 r/min

αSTEP AZ Series DC Input mini Driver

This is a mini driver designed to be more compact and lightweight than a box-style driver. Also compatible with battery power supply, so it can be used for an even wider range of applications than before.

Modular Automation Related Products

A robot controller that allows you to easily set up, program, and run the robot you have created with the AZ Series.

Supported Protocols: EtherNet/IP

Axial flow fan with 24 VDC input suitable for ventilation and cooling. In addition to the fan without alarm, there are 4 other functions available (with alarm/long life/variable speed/waterproof) to suit your application.

- New Concept Proposal From Oriental Motor for the Future of Mobile Automation

- The Key to Flexibility is to Realize "Layout-Free" Automated Equipment and Lines.

- What is a Modular Automation Compatible Product?

- Modular automation compatible products Lineup Introduction

- Product Application Examples

- Examples of In-House Production of Equipment

- Modular Automation Compatible Products

- Modular Automation Related Products