New Entry Into the Agribusiness Through Equipment Automation

Add-one Farm, Inc.

Establish an agricultural business with a small number of workers in a short period of time through highly efficient operations.

Add-one Farm, Inc. was established in 2010 as the agricultural business arm of Hokkou Corporation, which designs and constructs plastic greenhouses and other horticultural facilities. The company owns two solar-powered greenhouses, one in Okadama, Higashi-ku, Sapporo, and the other in Sakura, Toyoura-cho, Sapporo, with a total area of approximately 10,000 square meters. The entire Add-one Group, which operates throughout Japan, engages in hydroponic cultivation of vegetables with the aim of achieving both profitability and a safe and secure brand.

We interviewed Mr. MIYAMOTO, President of Add-one Farm, about the equipment that uses Oriental Motor products, as well as the background of the company's involvement in the "automation of agriculture," which is currently gathering much attention.

Chapter 1: Background and Challenges of Agricultural Entry

Seeking profitability, the concern was always, "How can we increase production efficiency with a small number of workers?”

Please start by telling us how your company got into agriculture.

Automation and high efficiency in the Netherlands, an advanced country in agriculture and horticulture, have been attracting attention, and companies in Japan have been working on such projects since 2006. Our parent company, also decided to focus not only on building greenhouses, but also on creating systems for internal facilities and cultivation, and established our company as an agricultural production corporation.

Smart agriculture and agricultural automation have been the focus of daily features on TV, and in newspapers and magazines.

More recently, tours and inspections have increased considerably. There are about two cases a week, sometimes four at the most. We often receive representatives from agricultural cooperatives and major corporations who are considering entering the agricultural industry from other industries. The hydroponics, air conditioning, and other facility gardening systems developed in cooperation with Hokkou have also been selling quite well. The new equipment has touch panels and can be operated remotely by PC.

Were you active in task automation from the beginning?

Yes. To be profitable, large-scale agricultural production had to be stable. When we began our efforts in 2007, there were only four or five employees, including myself, and we were always thinking about how we could increase production efficiency with a small number of people. The greenhouses produce and ship 12 to 24 crops per year, year-round, depending on the type of vegetable. To achieve this, automation of the work was essential.

-

Using hydroponics, the company produces and ships about 30 varieties, including baby leaves, throughout the year. -

Chapter 2. Equipment Modification

We often hear people say, "We can't go back to the way things were before we installed the equipment”.

Hydroponic Planter Bed Driving System

The beds are movable to provide space for work between the hydroponic planter beds. The objective is to maximize the area under cultivation.

How does the equipment work?

An AC motor allows the bed to be moved from side to side. A single motor drives the bed, which is over 30 meters long. The conventional method was to use rollers, but this method requires laying rails on the ground, which has the following problems: stumbling over the rails, difficulty in running the work cart, and difficulty in installing a large number of rails horizontally. In the case of Koro, we thought that the advantage was the free range of motion of the left and right sides, but we came to the conclusion that it is actually not necessary to move them that much, so we reviewed the mechanics and made improvements to the present device. It is sufficient if the space is wide enough for a person and a work cart to pass through.

-

Move beds longer than 30 meters to provide working aisles.

Easy to work with no obstacles underfoot. -

Mobile beds lined up neatly in the house.

Work is also a bit of a challenge. -

With a device that combines an AC motor with a new mechanism,

the bed can be driven left or right.

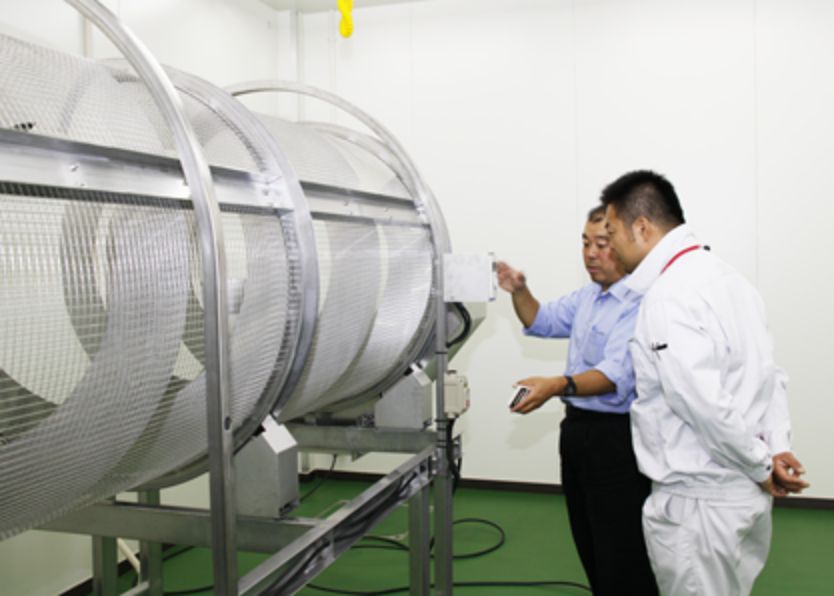

Automatic Sifter for Leaf Dirt Removal

The purpose of this equipment is to sift out roots and dirt from the harvested baby leaves. A chain sprocket combined with a brushless motor rotates a large sieve basket. Prior to the introduction of this equipment, sieving was done manually. The process of mixing multiple leaves was also spread out on a large desk and stirred by hand. Both tasks were hard work, and we often hear employees say, "We can't go back to the way things were before we installed the equipment now”.

-

A large sieve net is rotated to sift out roots and dirt. -

The equipment is also used to mix leaves of multiple species. -

Chain-based mechanism.

It is driven by a single brushless motor with dustproof and drip-proof capability. -

The driver makes it easy to operate the equipment and change speeds.

Chapter 3. Deciding Factors for Adoption

We are satisfied with the same-day shipping and the follow-up system.

We used to purchase AC motors from other companies, but since they were manufactured overseas, we were not able to be flexible in terms of delivery dates, and we often could not get them within the desired delivery time. That's when I was introduced to Oriental Motor. Depending on the number of units, the speedy delivery time, with same-day shipping, was what was first attractive. I had heard of the company's name, and the fact that it was a domestic product gave me a sense of security. After researching the company, I decided to go with them because of their excellent after-sales service.

How about post-employment communication and support?

I am very grateful for the free after-sales service and close communication, as well as the comprehensive support to make Oriental Motor products easier to use, such as when the sales staff worked with us, making suggestions as we considered new equipment. With large manufacturers, it was often difficult to get in contact with them with my inquiries.

-

Add-one Farm President MIYAMOTO. -

Chapter 4. Future Prospects

Further improvement and thorough automation lighten the load.

What are your plans for the future?

I would like to improve and automate the leaf mower. Right now, the employees are mowing, but at the Tomakomai site, for example, there are 144 hydroponic beds in a row, so that work must be done constantly throughout the day. Because Add-one Farm aims to make it possible for anyone to set up production activity that is viable economically in a short period of time, improving the equipment is a point that should be thoroughly addressed.

Finally, what you would like to see from Oriental Motor?

In the field of agricultural automation, there are many things that are powered by motors, such as harvesters, sifters, seeding, opening and closing windows for air conditioning, and so on. In this sense, we hope to see a succession of products that are long-lasting, high-performing, and environmentally friendly.

Credits

Add-one Farm, Inc.

Location: Sapporo, Hokkaido

URL:http://a-o.co.jp/index.html

Mr. Yuya MIYAMOTO, Representative Director

[Company Overview]

The company produces about 30 varieties of baby leaves, Salanova lettuce, salad spinach, mitsuba, green onions, and herbs, which are shipped throughout the year.

[Add-one Group Farm]

11 farms in total, in Okadama, Toyoura, and Tomakomai, etc.

Adopted Products

Hydroponic Planter

Bed Driving Unit

Induction Motors

Induction motors are suitable for applications that operate continuously in one direction. Also available are three-phase high efficiency motors with characteristics best suited for speed control by inverters, enabling energy saving.

For automatic sifters used in removal of roots and dirt from harvested products

Brushless motor BMU Series

The rotate and push setting dial for easy speed control, and the simple wiring allows you to connect the motor and driver by turning on the switch. The digital display can also show the actual operating speed. IP-compatible motors are also available.