How Should I Choose Geared Type for Stepper Motors?

-

Hmmm...

-

It seems like you're worried about something. What's going on?

-

The customer asked me to select a stepper motor for the drive of the index table. I've calculated the inertia ratio, but when I applied the value of the load inertia of the customer's mechanism to the calculation, the inertia ratio was so large there was no motor that meets the requirement even the αSTEP AR Series...

[Table (1)]

| Target Products | Inertia Ratio |

|---|---|

| αSTEP | 30 max. |

| Stepper Motors |

- *Except for geared type

-

Have you tried the selection calculation with the geared type? I recommend the geared type for a mechanism with large load inertia! Look at the formula in Table (2). By selecting a geared type, you can reduce the inertia ratio.

[Table (2)]

-

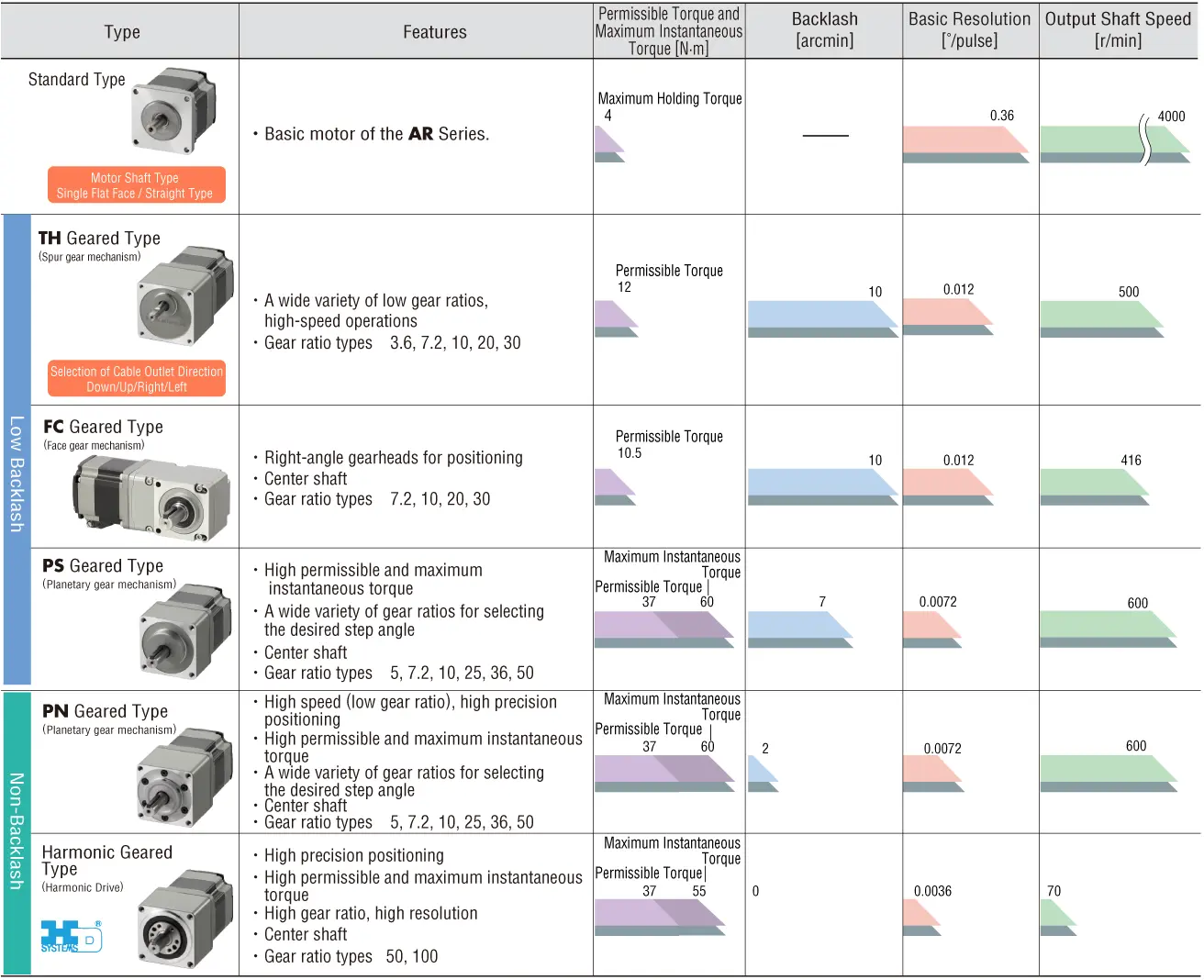

I see! For a geared type, the customer's mechanism will be fine. But there are so many types of geared type stepper motors that it seems difficult to choose...

-

-

Well, the permissible torque is different, and the backlash value is also different. I'm pretty sure backlash refers to the play between the gear teeth on the gearhead, right?

-

That's right. We need to confirm that the torque required to drive the equipment is within the permissible torque, and also what safety factor is obtainable. In addition, unlike AC motors, stepper motors require positioning accuracy, so the backlash value is also an important factor in selection.

-

I see! You can't choose just by calculating the inertia ratio and torque. We should confirm the customer's positioning accuracy, and if stricter accuracy is required, we should recommend PN geared or harmonic geared. Oh, the variation of the gear ratio also differs from series to series. I wonder why there is an incomplete gear ratio, such as 1/3.6 or 1/7.2?

-

There's a clue in the resolution of the stepper motor. For example, how many degrees does the αSTEP AR Series that you're trying to select move per pulse?

-

Let's see...the αSTEP AR Series is 0.36˚ per pulse... Oh, at a gear ratio of 3.6, the output shaft of the gearhead will move 0.1˚ per pulse, so it's easy to determine the angle.

-

Right! It’s thought out well. The gear ratio must also be selected so that the resolution can be accurately divided into the angle that the customer wants to determine. If you choose a gear ratio that can’t be divided, the discrepancies will add up, right?

-

I understand. We also have to consider the customer's operating speed... Confirm the operation conditions and mechanism conditions again, and try selecting a geared type from the αSTEP AR Series.

-

The AR Series are high efficiency motors, so they generate less heat even during high frequency repetitive positioning.

-

OK. Since I don't have to worry about the drive duty, I can make suggestions for improving the takt time of the equipment.

-

It seems you're getting to understand the products a little bit better, but you need to prepare yourself well so you can make a selection calculations according to the customer's conditions.

-

Yes I will!