Which Motor is Suitable for Conveyor Low Speed Operation?

-

At this speed, the gearhead gear ratio should be... Okay, I've got it.

-

Wow, Mr. Vex. Are you using selection calculations?

-

Yes. It's a motor for a conveyor. I will try to get my answer to the customer today since they said it was urgent.

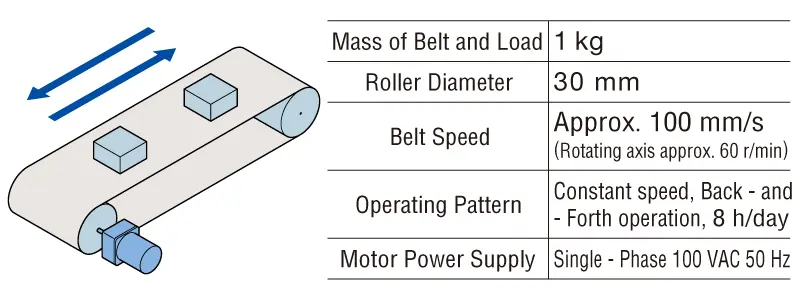

Figure 1 Selection Conditions

-

So how was the selection result?

-

I chose a reversible motor. The rotation speed is about 60 r/min, so I decided to use a gearhead with a gear ratio of 1/25.

-

Actually, at 60 r/min, there is an option not using a gearhead. Are there any way you can think of?

-

Well, is it an external speed reduction mechanism that uses pulleys and sprockets? That would require more components and space, but it is relatively cost effective and easy to do.

-

That’s a mechanical deceleration method, isn’t it?. You’ve really been hitting the books! What else is there?

-

Yes. There is a way to control the speed of the motor itself. It looks like inverters, brushless motors, and stepper motors can be selected. However, it requires a control circuit, which increases costs, and requires learning how to wire and set up, so some customers may be reluctant to do so. This time it is a constant speed operation, so it is over specification.

-

So is that it for all the alternatives, correct?

-

Ugh... If you put it like that... But I don't think there’s any more.

-

Actually, there is. There are low-speed synchronous motors. Low speed operation is possible without using mechanical speed reduction mechanisms or control circuits.

-

Low-speed synchronous? Like what I learned in my first-year workshop. But I don't remember that much. I'm sorry.

-

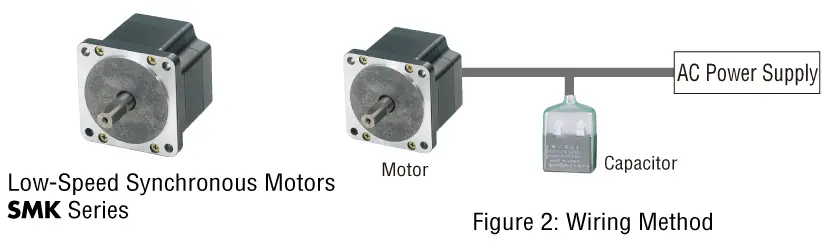

Nothing you can do about that. In a nutshell, it's a motor that rotates in sync with the power supply frequency. The structure is the same as a stepper motor, but the wiring is the same as an induction motor. All you have to do is to apply AC voltage and it will rotate at 60 r/min at 50 Hz and 72 r/min at 60 Hz.

Figure 2 Wiring Method

-

So it's a motor with unique characteristics, moving in sync with the power supply.

-

Then find a low-speed synchronous motor that meets the present conditions.

-

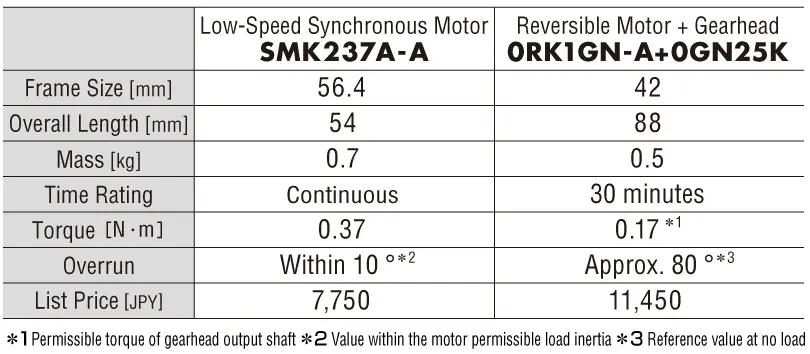

I think they can use the 56.4 mm frame size from the SMK Series. I compared it to the motor I selected earlier (Figure 3). It seems the overall length is shorter, and the overrun is smaller. Also, it's a great way to cut costs.

Figure 3 Comparison Table

-

For conveyors, there is also the point that the time rating is continuous. You can use it without worrying about the temperature rise of the motor, even if you use it repeatedly by back-and-forth operation.

-

I am surprised. So it's a motor that can be used for conveyors.

-

And it can be combined with a gearhead, so you can go even slower. For example, if an induction motor is generally operated at 1 r/min, what is the gear ratio at 50 Hz?

-

It’s 1/1500. You will need a 1/150 gearhead and a 1/10 decimal gearhead. We previously had a customer who needed the same combination for rotating a signboard.

-

In case of SMK Series, the gearhead with a gear ratio of 1/60 is all that is needed to achieve 1 r/min.

-

That's true! Since the decimal gearhead is eliminated, we can reduce the size and weight considerably. I use to select induction motors or reversible motors for constant speed applications, but I will also recommend the SMK Series from now on!

-

By the way, you're supposed to respond with the selection results by the end of the day, right? You better hurry.

-

Yes. Even if the motor is "ultra-low speed," I will do my best to work at "ultra-high speed."