How Do I Adjust the Rotation Speed of AC Motor?

-

Ms. Ori Let me check something. For AC motors, if you reduce the applied voltage, the speed will also decrease, right?

-

Was there an inquiry?

-

Yes. I was asked if we could adjust the speed by a transformer. The customer doesn't want to spend a time and effort on it, he is looking for an easy way to do it without removing the motor in use from the equipment.

-

You said, “It will decrease”, does that mean you think it will decrease?

-

That’s right! I remember doing experiments with motors when I was in elementary school. It rotated faster when 2 batteries were connected in a series than using 1 battery. I thought this meant that the speed of the motor changed depending on the applied voltage.

-

That's great, Vex. You were a studious child. But I think that experiment was done by DC motors. AC motors don't work the same way.

-

Huh? Really?

-

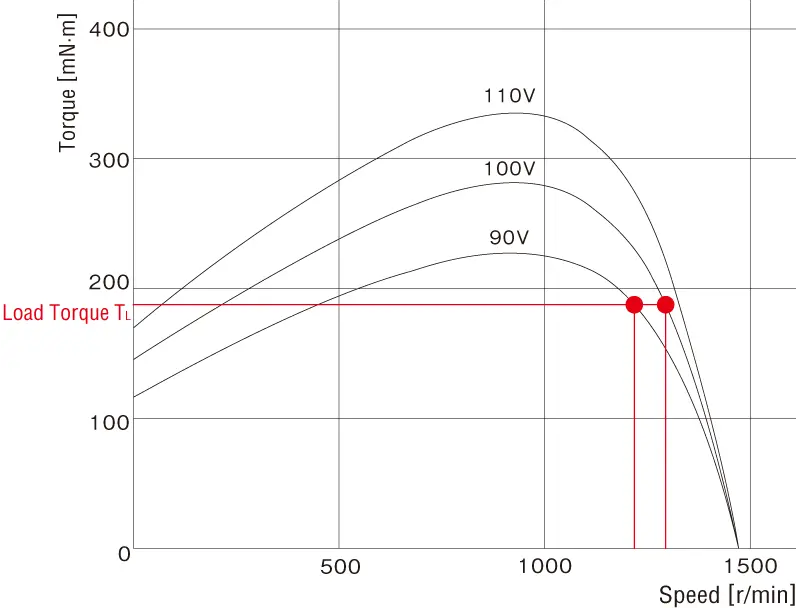

Look at the characteristics diagram below. The data shows the rotation speed - torque characteristics when the applied voltage is varied, and the line for the load torque TL are added. AC motors rotate at a point that's balanced to the load, so the intersection of the TL and each curve determines the rotation speed. So what happen?

Rotation Speed - Torque Characteristics

-

You have reduced the torque by lowering the voltage from 100 V to 90 V. However, the rotation speed hasn't dropped that much. I think it's about 80 r/min.

-

That's right. With AC motors, the torque changes by changing the voltage, so the speed also changes as a result, but the range of speed that can be adjusted is narrow. On the other hand, if the voltage is lowered too much, the torque will be reduced and it will not rotate.

-

I'd always thought the same way as DC motors. It seems AC motors are totally different. This means that the motor cannot be adjusted by itself, so I will introduce the control circuit as well.

-

Even though it's called a control circuit, you know that you can't use an inverter on a single-phase motor, right?

-

I know. Inverters are for three-phase motors. Well then, in addition to explain that Oriental Motor does not recommend using a transformer for speed regulation, I will introduce the customer about Oriental Motor's speed control motor.

-

Mr. Vex. There are 2 types of speed control motors, but are you sure you can explain each one?

-

Well, I'm a little unsure about that, so I'll check and get back to you.

-

Vex, refer to this comparison table. This is a rough summary of the features of each that I created earlier.

Comparison Table

Comparison Items Speed Control Motors Inverter AC Speed Control Motors Brushless Motors Tips for Use - Keep the cost down and use it simply (outside of speed adjustment, nothing required)

- Operates at a relatively stable speed even if the load changes

- Adjusts from low to high speed

- Operates at a stable speed even if the load changes

- Speed adjustments can be made without changing the motor in use (only for three-phase induction motors)

- Runs multiple motors with one inverter (V/F control only)

Power Supply Input Single-phase power supply Three-phase power supply/Single-phase power supply/DC power supply Three-phase power supply/Single-phase power supply

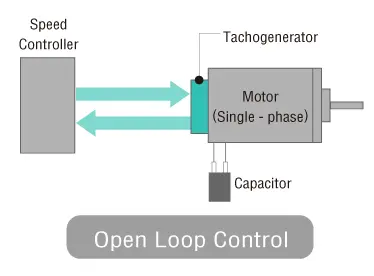

(Depends on the inverter)Motor Output Power 6~90 W 15~400 W 30~200 W Composition For single-phase induction motors

Equipped with a tachogenerator

+

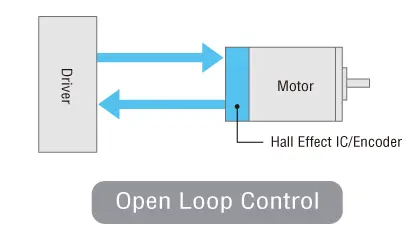

Speed controllerEquipped DC motors with a hall effect IC

(Some encoders are equipped)

+

DriverThree-Phase Induction Motor

+

Inverter

Control Target Speed Speed

(Some torque and position are also possible)Speed Rotation Speed*

(Speed Ratio)50 Hz 90~1400 r/min (1:15)

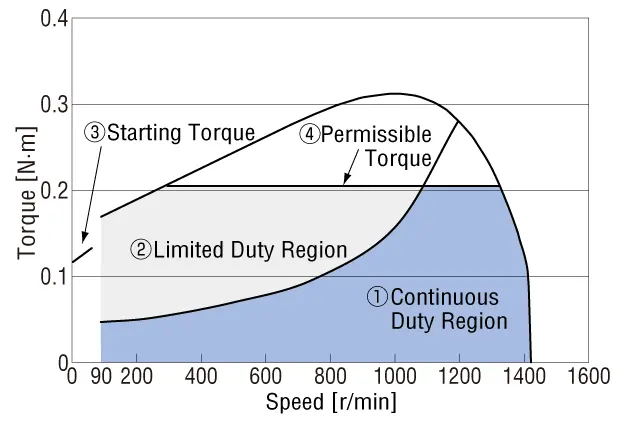

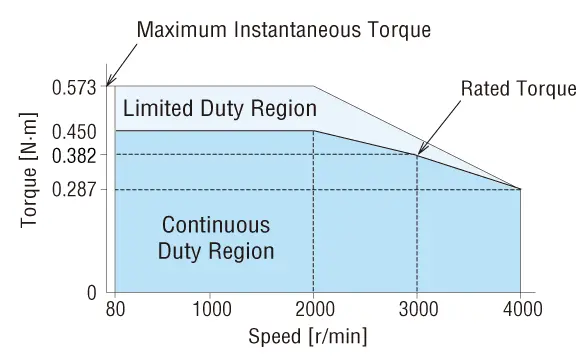

60 Hz 90~1600 r/min (1:18)80~4000 r/min (1:50) 90~3600 r/min (1:40) Speed Regulation With Respect to the Load* ±1 % (Reference value) ±0.2 % -5.5 % (Reference value) Torque Characteristics

List Price (Online Shop Price)* 28,050 JPY (23,840 JPY) 32,400 JPY (27,540 JPY) 27,190 JPY (25,420 JPY) - * The following products are listed as examples.

AC Speed Control Motor: US2 Series

Brushless Motor: BMU Series

Inverter: KIIS Series + General Inverter

The price assumes a combination of a 100 W class motor + circuit.

-

What is this? It's so easy to understand! Please give me one, too!

-

I'm sure I also gave it to you when I was training you as a new employee. Did you lost it?

-

No... I still have it. Probably...

-

Then get yourself together. There are many differences in characteristics and functions, but I'll briefly explain some of the main points of use. First of all, let me tell you about AC speed control motors. They are easy to use and affordable. The US2 Series in particular has simple wiring, so I can get it up and running in no time. Watch this video.

Speed Control Motor US2 Series Simple Wiring

-

It is really simple. I also recommend it because a power supply cable with a plug for single-phase 100 VAC is included. It is popular with customers who want to plug it in and run it right away.

-

You just have to be careful about the characteristics, Vex. As you can see from the rotation speed - torque characteristics, the low speed range of the AC speed control motor has a narrow continuous duty region. It's fine for short periods of operation, but if you're going to use it continuously, you need to be careful of the heat generated by the motor. AC speed control motors have the advantage of being easy to use, but this is a point that should be conveyed to customers when introducing them.

-

I won’t forget to tell about it.

-

So next up, brushless motors. Brushless motors are adjustable from high to low speed, and have lower speed regulation. Do you remember the speed regulation with respect to load?

-

I remember you once taught me by "Does a Brushless Motor Lose Speed Under Increased Load?". Simply put, the smaller this value is, the more faithful the rotation will be to the setting value, right?

-

That's right. I recommend if you want to keep the rotation speed constant even when the load changes.

-

For example, in what kind of usage can you find the speed regulation with respect to the load?

-

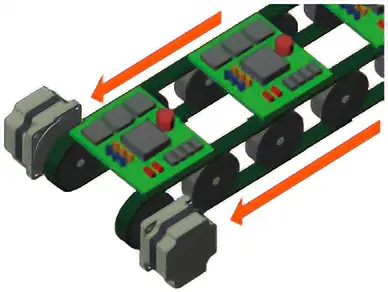

There are a lot of different types, but I think 2-row conveyors, grinders, and agitators would fit the bill.

-

2-Row Conveyors

-

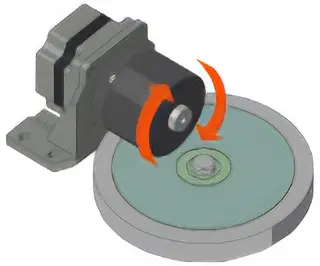

Polishing and Deburring Machines

-

Agitators

-

-

That's because a 2-row conveyor requires 2 motors for rotation at the same speed, and it’s best for a grinder to rotate at the same speed even if the load increases due to friction between the grindstone and the load. But why is the speed regulation with respect to load found for agitators?

-

Agitators are mainly used to stir things like foods and chemicals, but these do not only vary in their original viscosity, but some also change as they are stirred. For agitators that you want to stir at a constant speed even if the viscosity changes, it's better to have low speed regulation with respect to the load.

-

I see. Brushless motors are the best choice for sure.

-

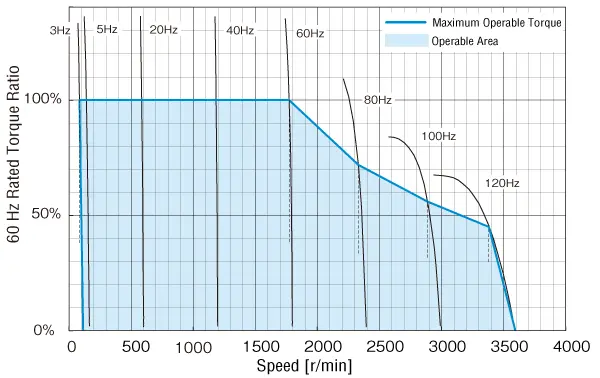

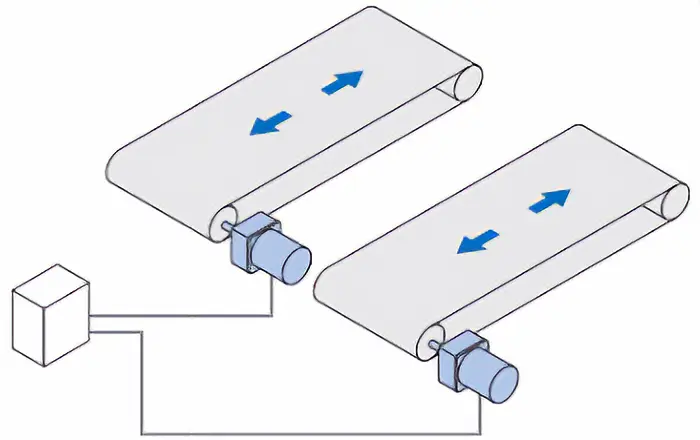

And one more thing. As I mentioned earlier, there is also the option of using inverters. If it's a three-phase motor, you can simply add it later, so you can easily perform speed control. Also, a single inverter can control multiple motors (multi-axis control), which is a feature that is not found in AC speed control motors or brushless motors.

Example of Multi-Axis Control (Belt Conveyor)

-

It seems easy and good if you want to run multiple motors in the same way. But how is that possible?

-

This is possible because unlike the other two, the status of the motor is not being monitored (open loop). However, multi-axis control depends on the function of the inverter, so you need to check before you select. Also, note that inverters and three-phase motors have different characteristics depending on the combination. For the KIIS Series, the combination characteristics data is available on the website, so be sure to guide customers there as well. I think it will reduce the burden on customers when they design. Oh, Vex. It's about time to answer the questions to the customer.

-

Yes. Now, after confirming with the customer what motor they are currently using and how they are using it, we will introduce the "AC speed control motor," "brushless motor," and "inverter + three-phase motor."

-

The differences in the structure and operating principles of each are explained in detail in the e-learning "Using Different Speed Control Motors" on the website, so please introduce to our customers as well.

-

Yes. I'll take a look beforehand too.

-

You should also look for my comparison chart and review it.

-

…Yes.