Manufacturing Robots In-House: Easier Than You Think!

Demand for robots has been increasing in recent years as factories seek to improve productivity and save labor through equipment automation. At the same time, however, commercially available industrial robots are large and difficult to install on production lines. Moreover, their high cost often poses an obstacle to their adoption.

As a result, companies often consider manufacturing robots in-house, but are unable to proceed due to the high hurdles involved in selecting components and the challenges of controlling the robots. It is against this backdrop that Oriental Motor released its αSTEP AZ Series of robot manufacturing motors and MRC01 controllers to simplify the production and control of robots. In addition, we offer a variety of services to facilitate the in-house production of robots. In-house robots can be designed to meet the exact needs of your factory's production lines, and are less expensive than commercially available robots.

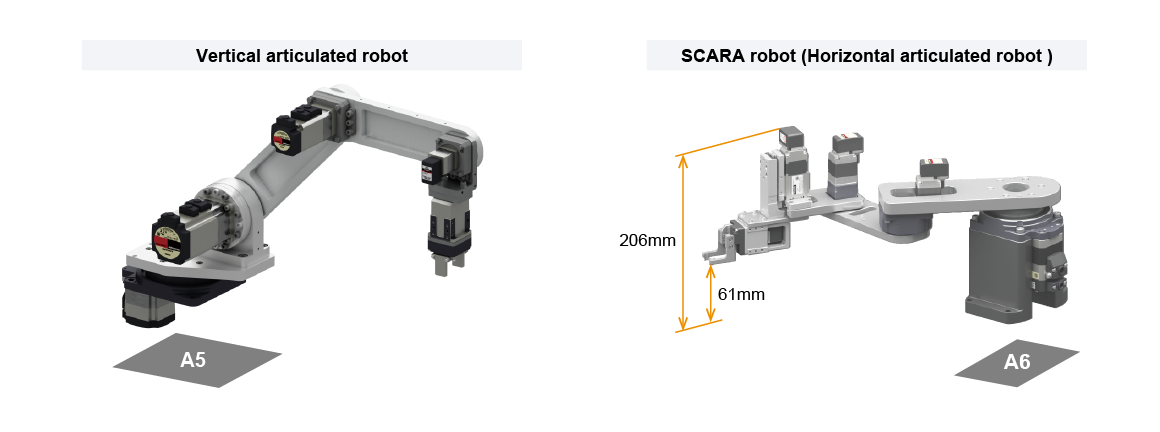

Installable on Existing Production Lines - Compact Design for Limited Spaces

Many commercially available industrial robots are large, making them difficult to install in limited spaces. Production lines would need to be reconstructed to accommodate the robots. However, the costs and labor required to do this would not be feasible when only automating simple tasks. In contrast, companies can design in-house robots to meet their needs, including small tabletop vertical articulated robots and low-floor transportation SCARA robots. In-house robots are easy to install on existing production lines.

Factory production lines optimized by in-house robot manufacturing

If you design an in-house robot to meet your company needs, it can be flexibly manufactured according to the actual space and operation specifications, allowing you to smoothly automate tasks in your factory. For example, the installation space for a vertical articulated robot is approximately 130 x 170 mm. This footprint is smaller than the size of A5 paper, enabling it to be installed in a space-efficient manner.

Click here to see examples of in-house SCARA robots manufacturing

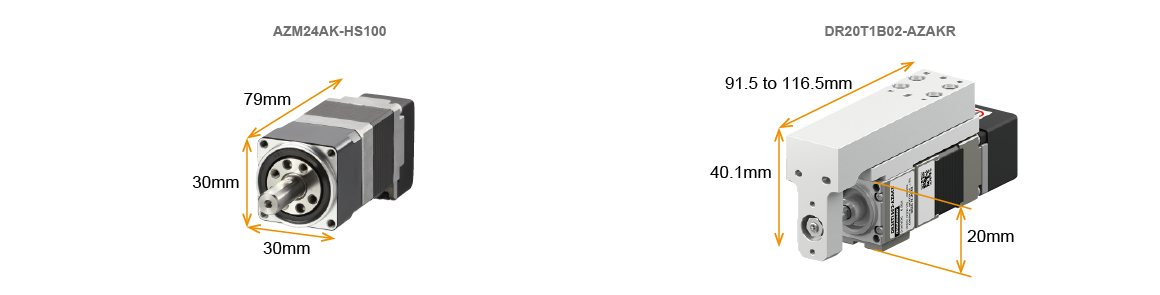

Production of compact robots using small motors

When manufacturing robots for limited spaces in-house, all the parts must be miniaturized, including the motor. Oriental Motor offers an extensive lineup of compactly designed motors and linear and rotary type actuators, such as those in our αSTEP AZ Series. Manufacturing robots in-house enables them to be smaller.

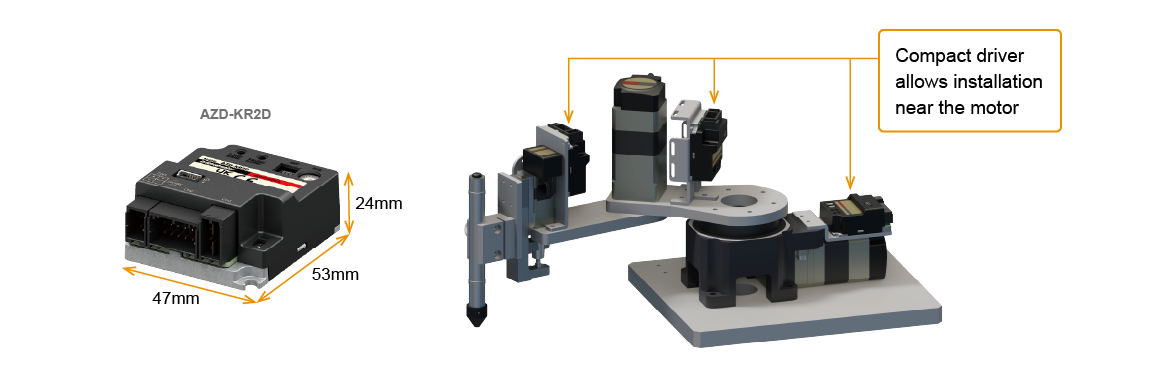

Compact driver that can be positioned with a high degree of flexibility

Driver size must not be overlooked when creating small in-house robots. Compact drivers can be installed in the smallest of spaces and can be flexibly positioned without being constrained by the location of the power distribution panel. For example, if the driver is installed right next to the motor, less motor cable will be needed. This creates a cleaner production site with less wiring.

Click here to learn more about AZ Series mini Drivers

Intuitive Control, Easy Creation of Robots - Achieve Labor Savings and Factory Automation with Facilitate Deployment

Robots use multiple motors, resulting in many design burdens, such as how to mechanically design gears and ball screws, how to arrange sensors, and how to design the wiring. To design a multi-axis robot, in-house manufacturers would have to face many programming and control hurdles. To overcome these challenges, Oriental Motor offers a lineup of controllers that are easy to program and control, as well as motors and actuators that reduce design burdens.

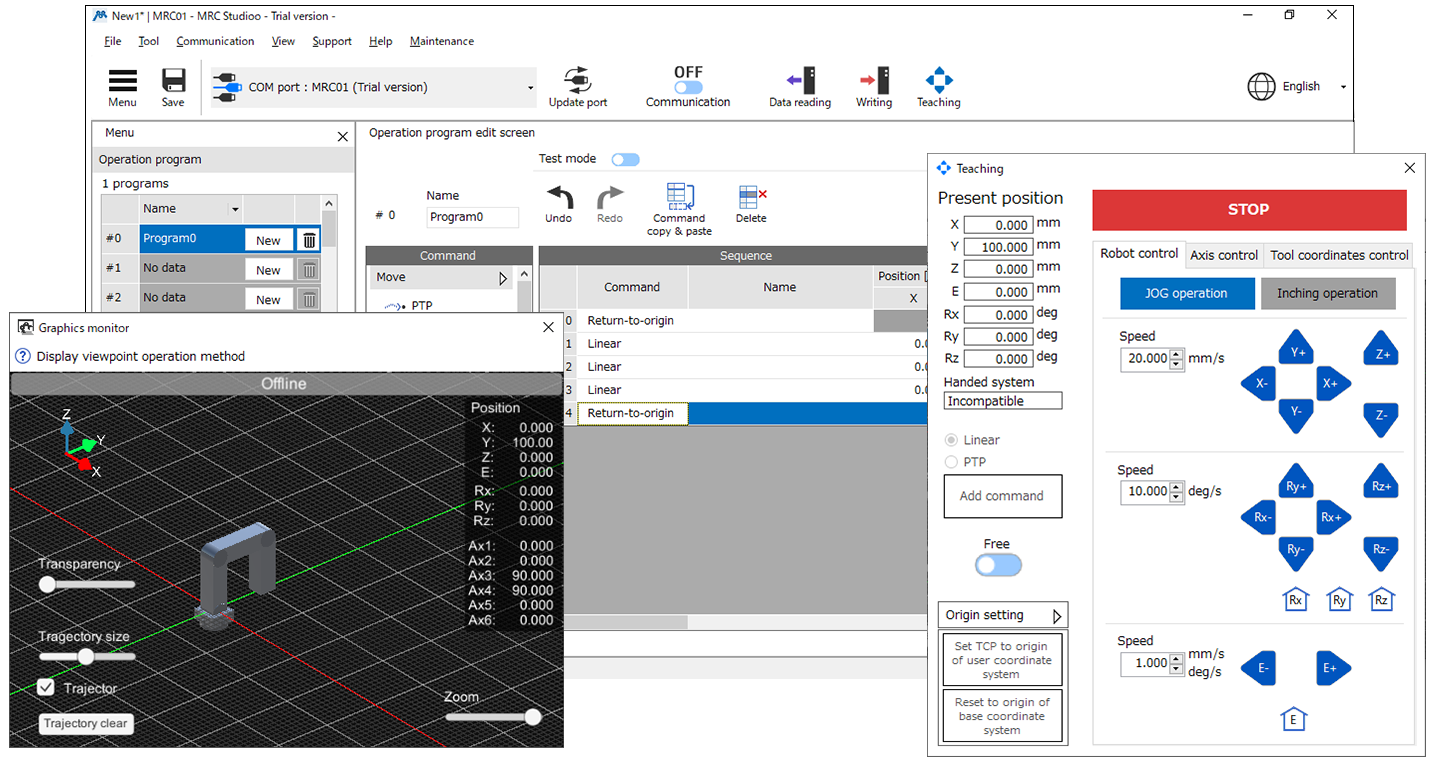

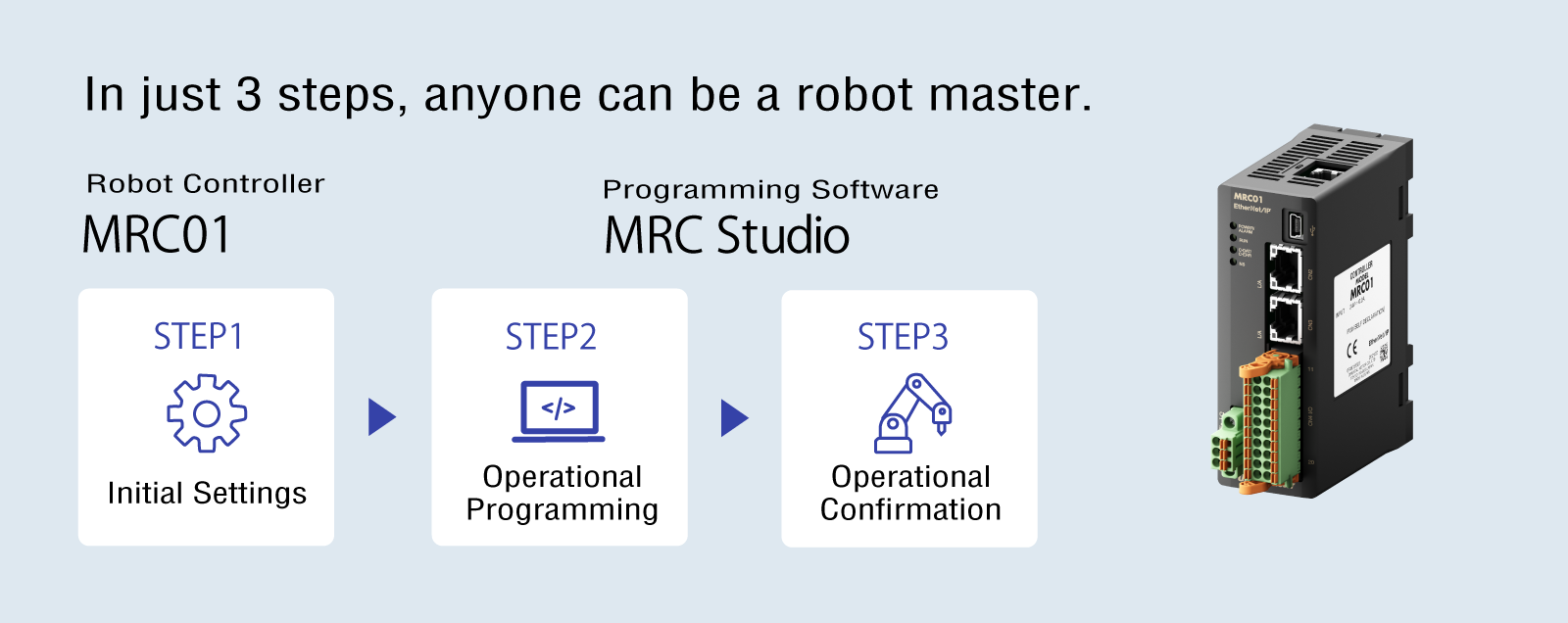

MRC01 makes it easy to control robots

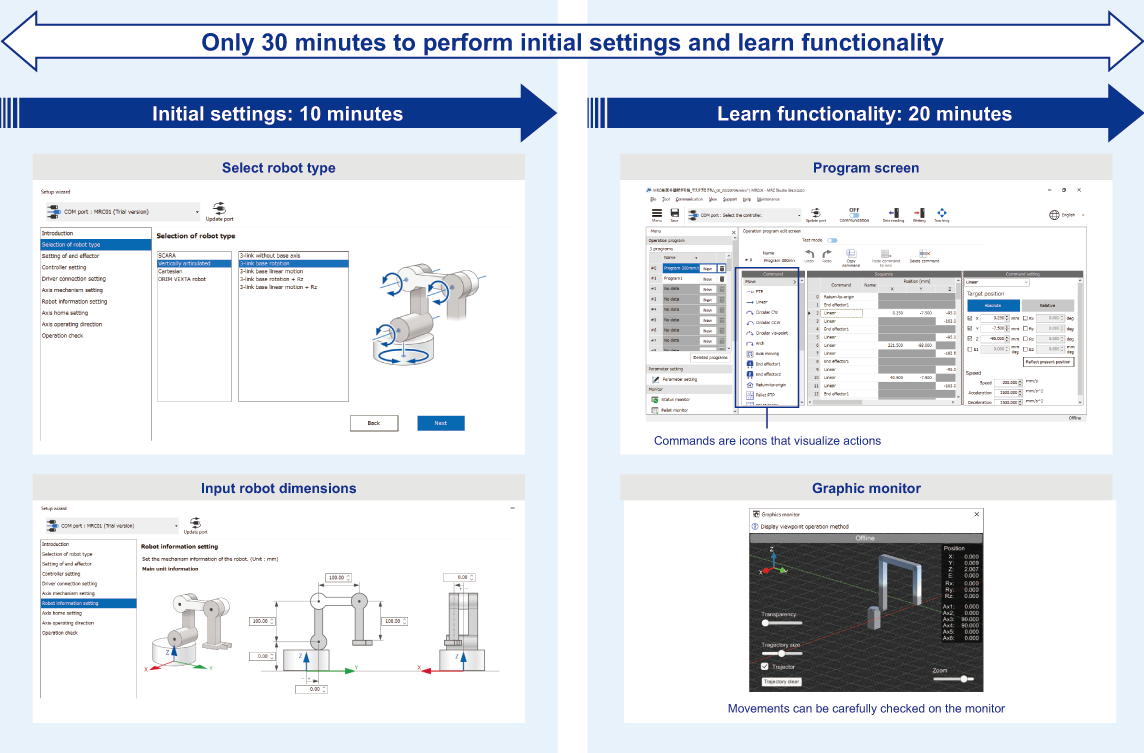

We have developed a robot controller MRC01. The dedicated programming software MRC Studio enables even inexperienced robot designers to quickly program and control robots. MRC01 reduces programming and control hurdles and makes it easy to start producing robots in-house.

Learning curve of only 30 minutes

Even inexperienced robot designers can master MRC Studio in about 30 minutes. This includes 10 minutes for initial setup and 20 minutes for learning software functionality.

αSTEP AZ Series reduces design burdens

Many different parts are needed to manufacture a robot, including motors, gears, ball screws, arms, and robot grippers. As the number of parts increases, so does the burden of designing and managing them. Moreover, if the type of motor needs to be changed due to a different usage environment, the use of the robot would have to be learned all over again. The AZ Series reduces these burdens.

Click here to learn more about AZ Series

Offers a wide range of variations to reduce the burden of learning how to use robots

The AZ Series includes a complete lineup of motors and mechanical components such as gears, sliders, tables, and grippers. This reduces the burden of the mechanical design required of gears, ball screws, and other components.

Furthermore, if all moving robot parts are AZ Series products, not only can usage be standardized, but the commonality of parts such as cables and drivers reduces the burden of parts procurement.

Sensorless design reduces the burden of sensor wiring and procurement

The AZ Series comes with a battery-less multi-turn absolute sensor that retains position information even when powered off. This reduces the burden of designing and arranging the wiring of the home sensor and limit sensor.

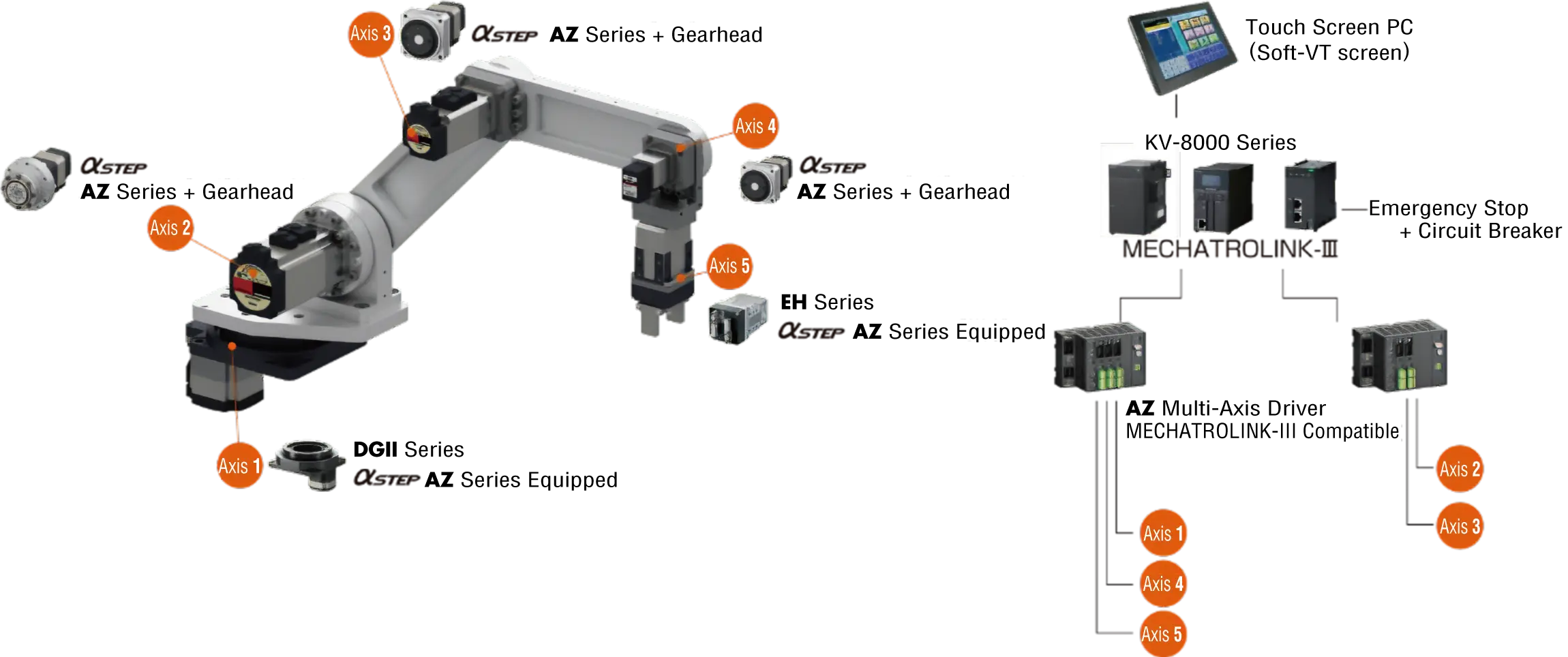

AZ Series products work with other company controllers

When designing the control operations of equipment, it may be necessary to use controllers other than MRC01 products. Since each controller has different communication specifications, it is necessary to use a motor that matches these specifications. The AZ Series provides a lineup of drivers that support various industrial networks, including EtherNet/IP, EtherCAT, PROFINET, SSCNETIII/H, and MECHATROLINK-III. Even when using the robot controllers of other companies, it is still possible to take advantage of AZ Series variations and sensorless design features.

- *EtherCAT is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- *EtherNet/IP is a trademark of ODVA.

- *Harmonic Planetary and Harmonic Drive are registered trademarks of Harmonic Drive Systems Inc.

- *MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

- *SSCNETIII/H is a registered trademark of Mitsubishi Electric Corporation.

Reduce Deployment Costs and Maximize Cost-Effectiveness

Generally, when companies consider introducing robots, they find that the cost can be as high as several thousand dollars. However, when a robot is manufactured using Oriental Motor products, it can often be produced for approximately SGD$10,000. This significantly reduces the cost of deploying robots.

For example, a 5-axis vertical articulated robot costs approximately SGD$10,000 to produce when using Oriental Motor products (motors, actuators, drivers, cables, controllers, and software)*1. In addition, robots can still be manufactured relatively inexpensively, even when using the parts of other companies*2.

- *1 Calculated using our online store prices (Excluding tax)

- *2 Arms, mounting plates, grippers for hands and other parts can cost several hundred dollars (excluding PLCs and electrical systems).

List of Components

You can easily build your own robot with the AZ Series,

and robot controllers that can be configured and programmed are also available.

- *The MRC01 is not used in this demonstration unit.

Motors and Drivers

| Axis | Product Name | List Price (SGD) | List Price (USD) | |

|---|---|---|---|---|

|

Axis 1

|

Hollow Rotary Actuator | DGM130R-AZAK | SGD 2,406 | USD 1,925 |

| Driver | AZD-KR2D | SGD 468 | USD 374 | |

| Connection cable | CCM030Z2ABF | Contact Us | Contact Us | |

| Power supply cable | LCD06Z2AY | SGD 20 | USD 16 | |

|

Axis 2

|

Motor*1 | AZM66MK-HS100 | SGD 1,725 | USD 1,380 |

| Driver | AZD-KR2D | SGD 468 | USD 374 | |

| Connection cable | CCM030Z2ABF | Contact Us | Contact Us | |

| Power supply cable | LCD06Z2AY | SGD 20 | USD 16 | |

|

Axis 3

|

Motor*2 | AZM46MK-HS100 | SGD 1,288 | USD 1,030 |

| Driver | AZD-KR2D | SGD 468 | USD 374 | |

| Connection cable*3 | CCM030Z2ABF | Contact Us | Contact Us | |

| Power supply cable | LCD06Z2AY | SGD 20 | USD 16 | |

|

Axis 4 |

Motor*3 | AZM24AK-HS100 | SGD 1,049 | USD 839 |

| Driver | AZD-KR2D | SGD 468 | USD 374 | |

| Connection cable*3 | CCM030Z2ABF | Contact Us | Contact Us | |

| Power supply cable | LCD06Z2AY | SGD 20 | USD 16 | |

|

Axis 5

|

Electric Gripper | EH4-AZAKH | SGD 908 | USD 726 |

| Flexible connection cable*1 | CC030VZ2RA | SGD 121 | USD 97 | |

| Driver | AZD-KR2D | SGD 468 | USD 374 | |

| Connection cable*3 | CCM030Z2ABF | Contact Us | Contact Us | |

| Power supply cable | LCD06Z2AY | SGD 20 | USD 16 | |

|

Control

|

Robot Controller | MRC01 | SGD 2,750 | USD 2,200 |

| RS-485 Communication Cables | CC02FLT6 | Contact Us | Contact Us | |

| SGD 12,687 | USD 10,147 | |||

- *1

- Actual equipment uses the AZM66MK in combination with Harmonic Drive System’s CSG-20-100-2UH-LW-SP-B.

- *2

- Actual equipment uses the AZM46MK in combination with Harmonic Drive System’s CSF-11-100-2UP-SP-C.

- *3

- Actual equipment uses the AZM24AK in combination with Harmonic Drive System’s CSF-8-100-2UP-SP-A.

Photo of a 5-axis vertical articulated demo robot

Watch the video on 5-axis vertical articulated demo robot applications

Low-cost controller with cost-free software

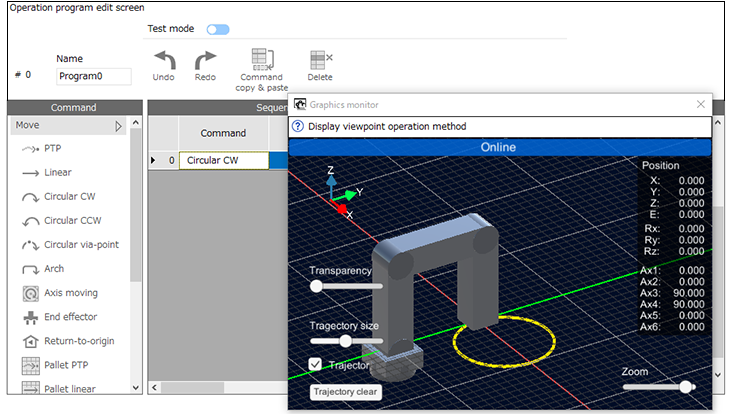

The MRC01 robot controller provides the basic functions required to operate robots at a low cost. In addition, users can download the dedicated programming software MRC Studio free of charge. Users can create programs intuitively without special knowledge of ladder logic and other programming concepts.

Users can download a trial version of MRC Studio to check if the operability suits their needs. The software can be used without MRC01. Robot actions can be observed using a graphic monitor.