Starting With Energy Efficient Motors

Reduction of CO2 Emissions by Using a Brushless Motor

Using an energy efficient motor in transportation, agitation, winding, and other forms of speed adjustment can reduce CO2 emissions by lowering the power consumption. Brushless motors are compact, high-efficient speed control motors with an on-board hall sensor and a dedicated circuit (driver) that performs feedback control.

The Effects of Using a Brushless Motor

Annual Power Consumption (Compared with output 60 W)

| Power Consumption (kWh/year) |

CO2 Emissions (kg/year) |

Electricity Charges (JPY/year) |

|

|---|---|---|---|

| AC Motors | 1,068.7 | 484 | 17,100 |

| Brushless Motors | 665.8 | 302 | 10,653 |

- Calculated at 24 Hours of Drive Time per Day, 365 Operating Days per Year, a Power-CO2 Emissions Conversion Coefficient of 0.453 kg–CO2/kWh, and Electric Utility Rate of 16 JPY/kWh

- The Usage Conditions are As Follows

AC motor: Output 60 W, single-Phase 200 VAC, 60 Hz

Brushless motor: BMU Series, output power 60 W

Power Consumption

Reduced by 402.9 kWh/year

CO2 Emissions

Reduced by 182 kg/year or 38 %

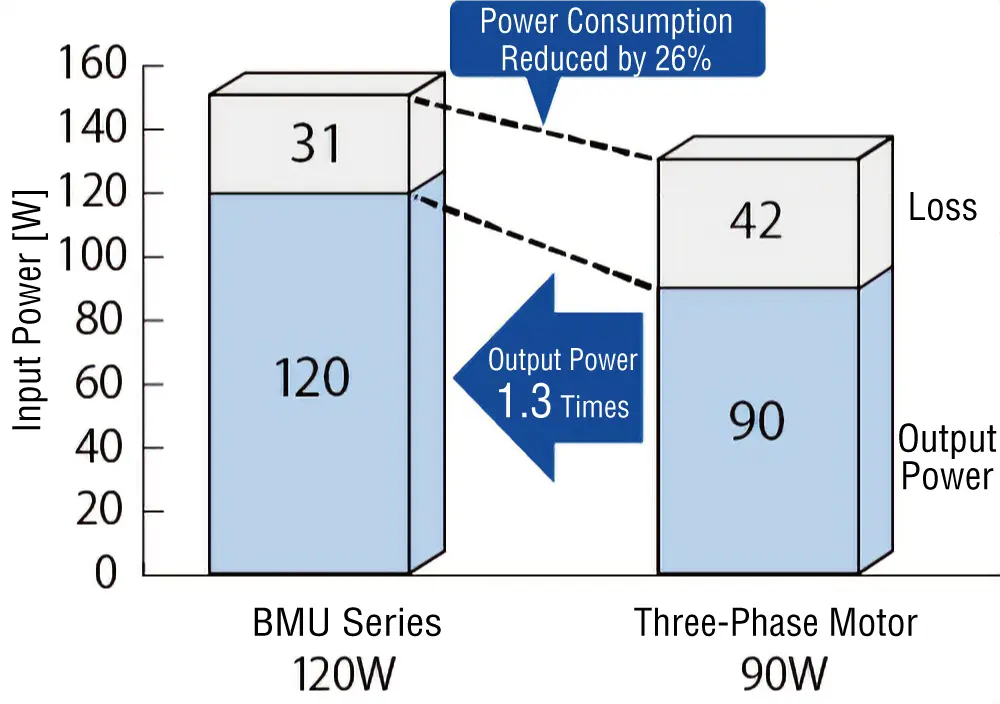

More Efficient than Inverter Control

Brushless motors, which incorporate permanent magnets in the rotor, generate little secondary loss from the rotor. This results in a roughly 26 % reduction in power consumption compared to a three-phase induction motor for inverter control*. This helps the equipment to save energy.

- *When output power is 90 W

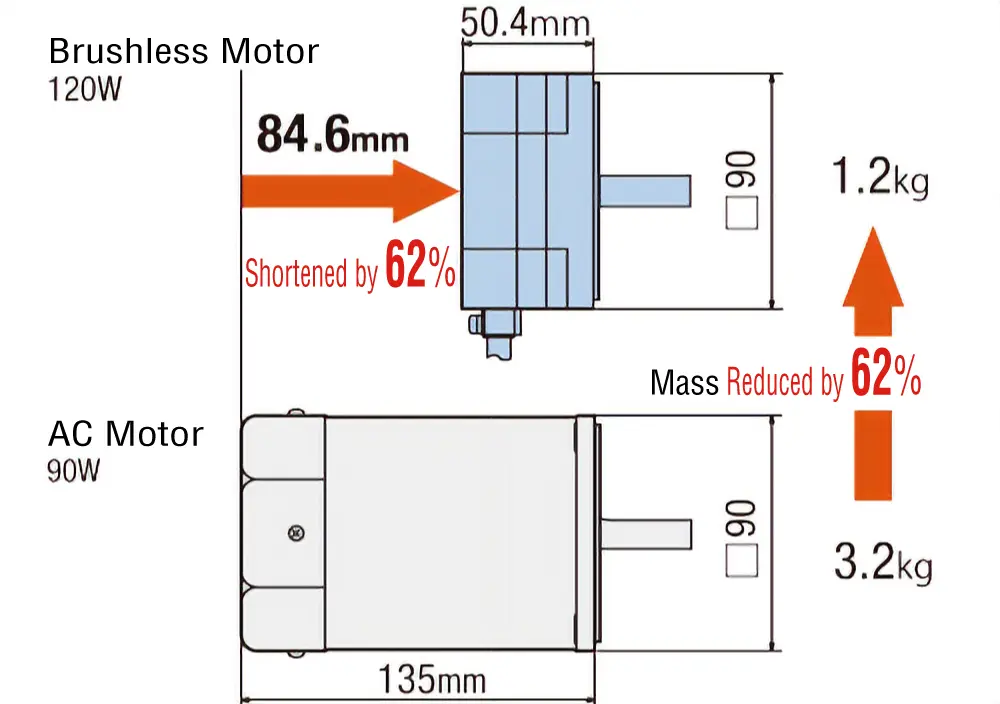

A Compact and Lightweight Motor Contributes to Resource Conservation

Brushless motors with built-in permanent magnets are slim and high-powered. For example, compared to a three-phase induction motor of frame size of 90 mm, their total length is 84.6 mm shorter. This contributes to equipment downsizing and the use of fewer natural resources.

Proposals for solving issues with automation and energy conservation

Compatible Products

Brushless Motors

A huge variety of motors are available, from types that offer easy speed adjustment with a dial to those that offer position control and network control. Select the motor that best suits your application.