Utilization Proposals of Motors in Accordance With Conservation Methods

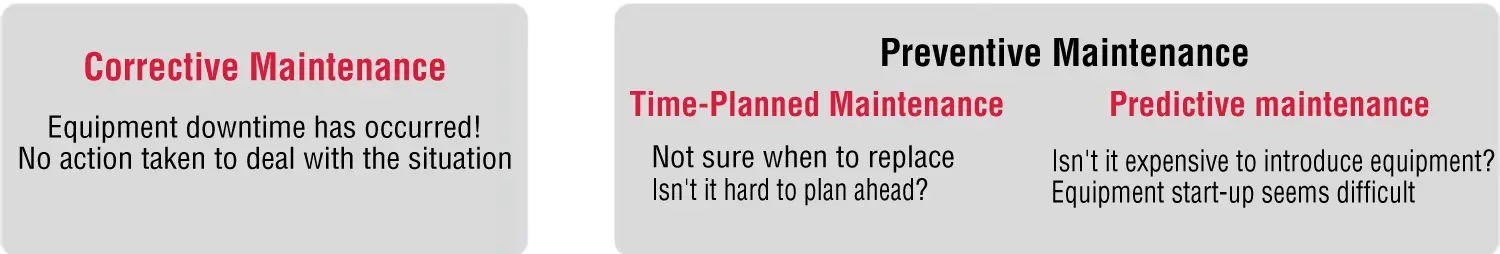

Do you have any of these concerns on site?

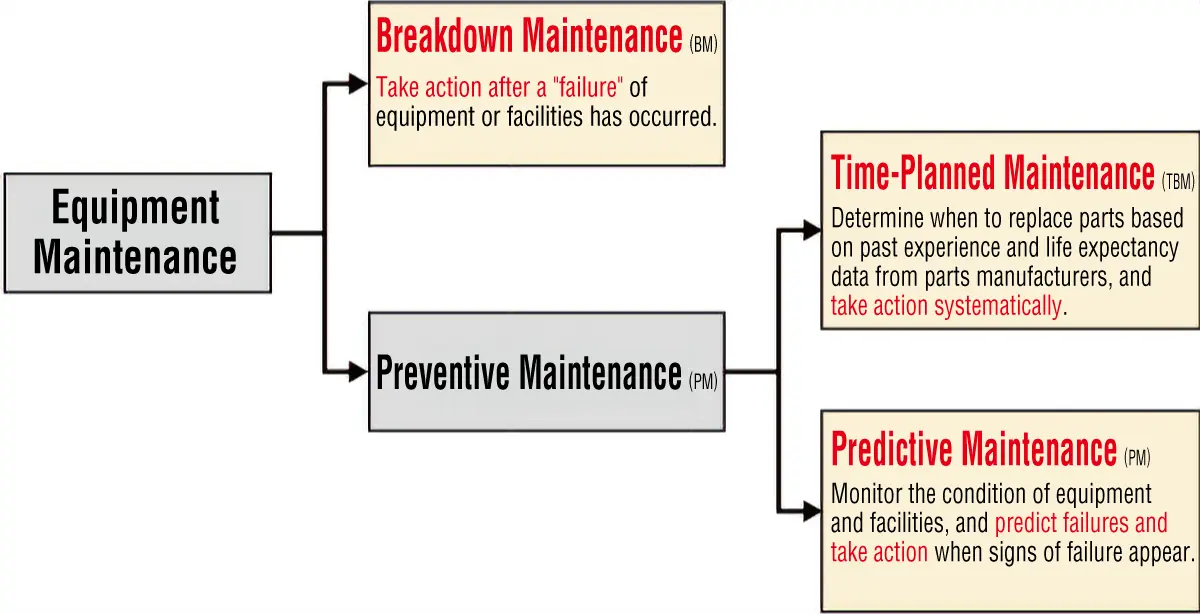

About conservation methods

| Conservation Method | Advantages | Disadvantage | |

|---|---|---|---|

| Corrective Maintenance | Simple and waste-free because it replaces failed parts. |

This is not appropriate for parts that have a major impact on equipment or facilities when they fail. |

|

| Preventive Maintenance | Time-Planned Maintenance | Since parts are replaced according to a plan, you are unlikely to have unexpected problems. |

If you don't know the replacement cycle of the parts, there will be a lot of waste. Sometimes you have to replace a part even though it is still usable. |

| Predictive Maintenance | Can help prevent problems before they occur. The parts to be replaced can be procured according to a plan without waste. |

Since it is necessary to collect and analyze the data necessary for monitoring, initial investment in sensors and other equipment as well as skills to judge the analyzed data are required. |

|

Oriental Motor’s extensive product lineup contributes to a variety of equipment maintenance.

Breakdown Maintenance The Alarm Function Makes It Obvious Where the Failure is!

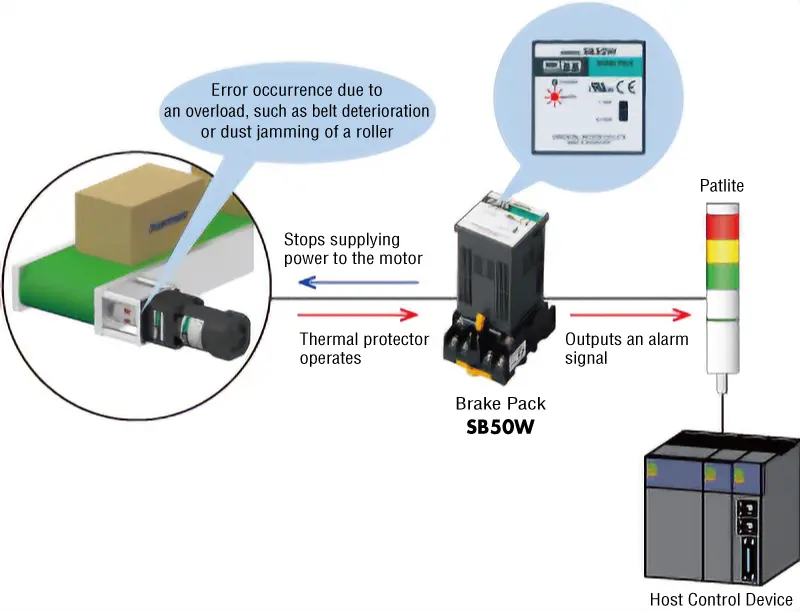

AC Motor+Brake Pack (Alarm function)

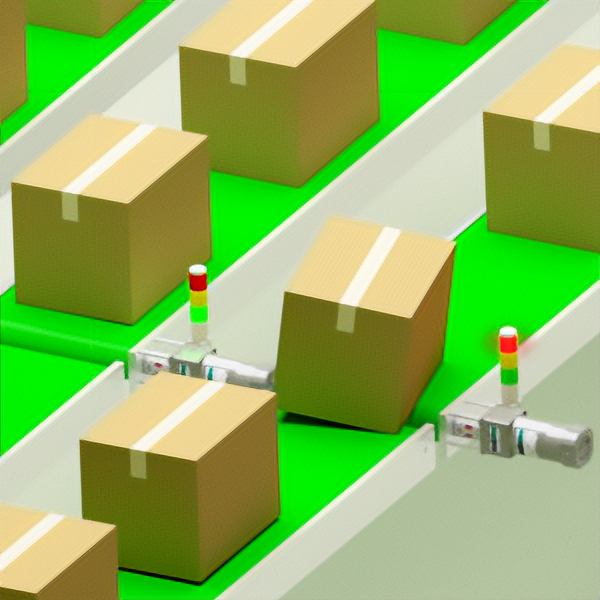

[Applications] Running Multiple Conveyors

In order to detect abnormalities on the conveyor, sensors such as speed sensors and load cells must be installed.

In the case of the AC motor + brake pack, the alarm output from the thermal protector detection function allows visualization of stops due to conveyor locking, such as load stops.

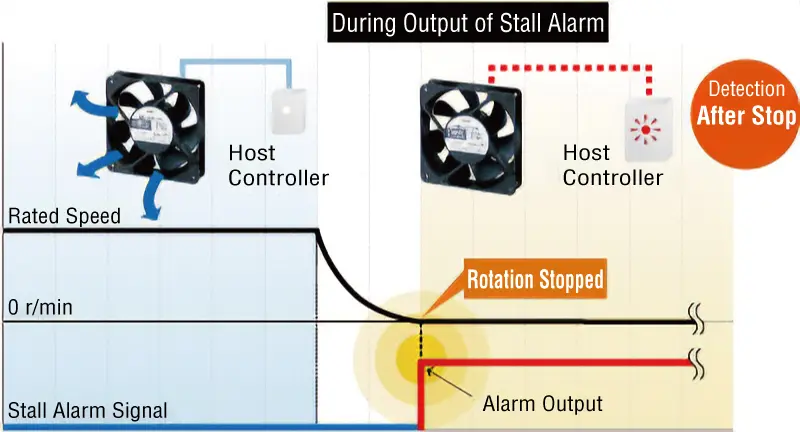

Fan with Stall Alarm

DC Axial Flow Fan MD Series A Type

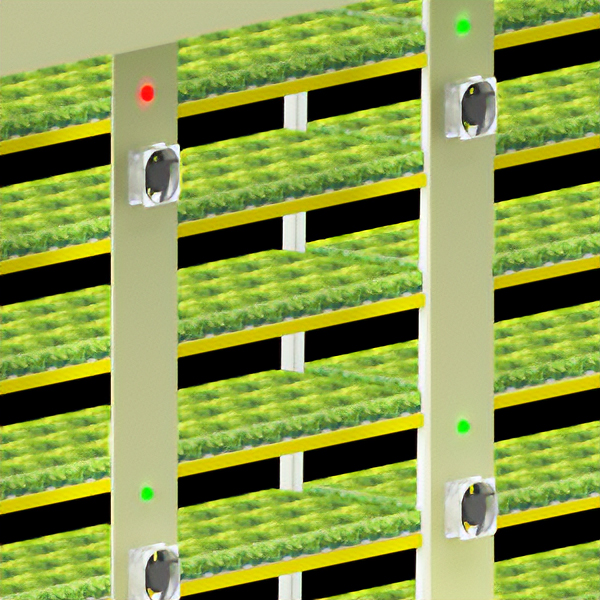

[Applications] When multiple fans are used for air agitation in a vegetable cultivation plant, etc.

It is difficult to confirm fan failure by external appearance when the fan stops for an indeterminate cause.

By outputting alarms from the fan, the failure location can be identified quickly.

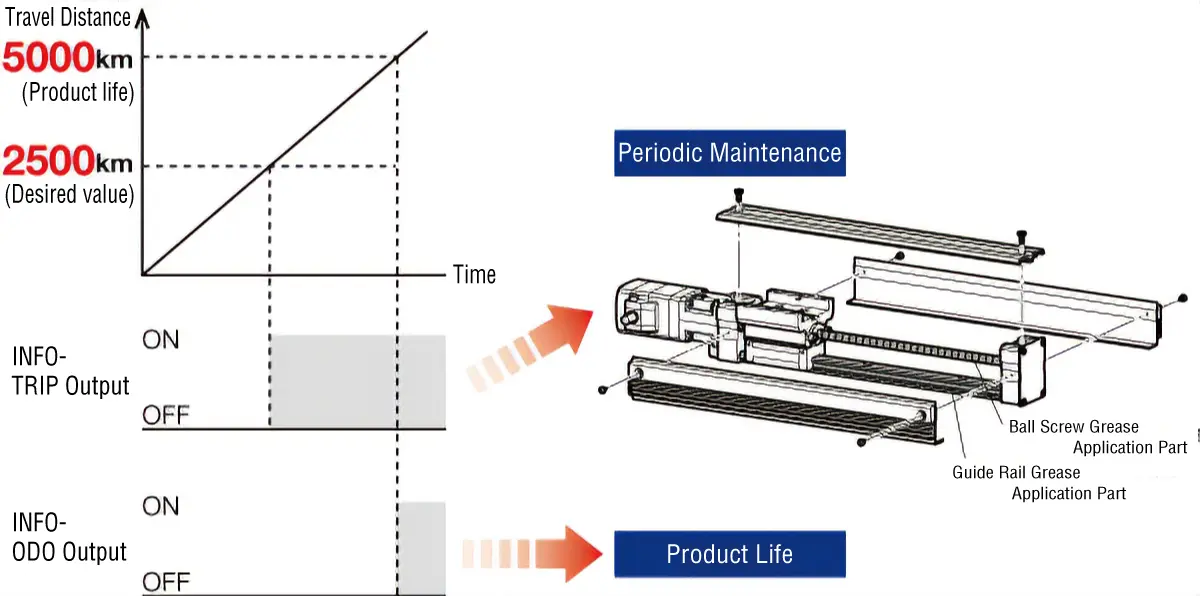

Time-Planned Maintenance Maintenance Information Function Contributes to Planned Maintenance!

Odometer and Tripmeter Information to Manage Travel Distance

The time and amount of operation can be determined in advance based on a rule of thumb and the lifetime of the parts shown by the manufacturer, and maintenance can be performed according to a plan.

Tripmeter Information

(INFO-TRIP)

This is output when the motor's travel distance exceeds the setting value.

Odometer Information

(INFO-ODO)

This is output when the motor's cumulative travel distance exceeds the setting value.

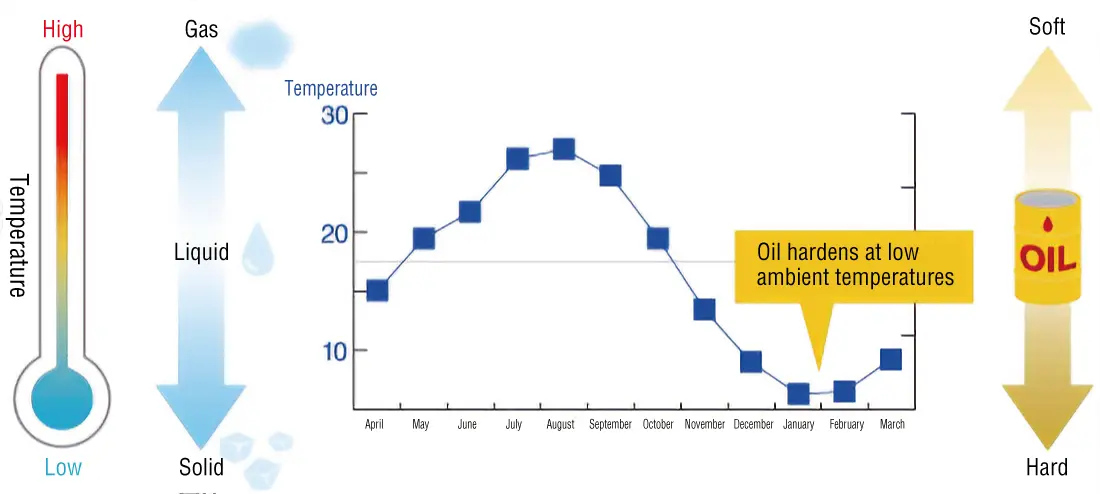

Predictive Maintenance Identifies Changes and Contributes to Timely Maintenance!

Constant Monitoring to Identify Changes in Status

Constantly monitors the condition of equipment and facilities, and performs maintenance when signs of "failure" are detected.

Case 1: Prevention by warm-up operation and grease-up

Identifies changes in increased load on the motor drive unit due to grease hardening over time.

This will help you to prevent sudden equipment stops by taking measures such as warm-up operation and greasing up when the equipment starts.

Case 2: Replacement at the end of product lifetime

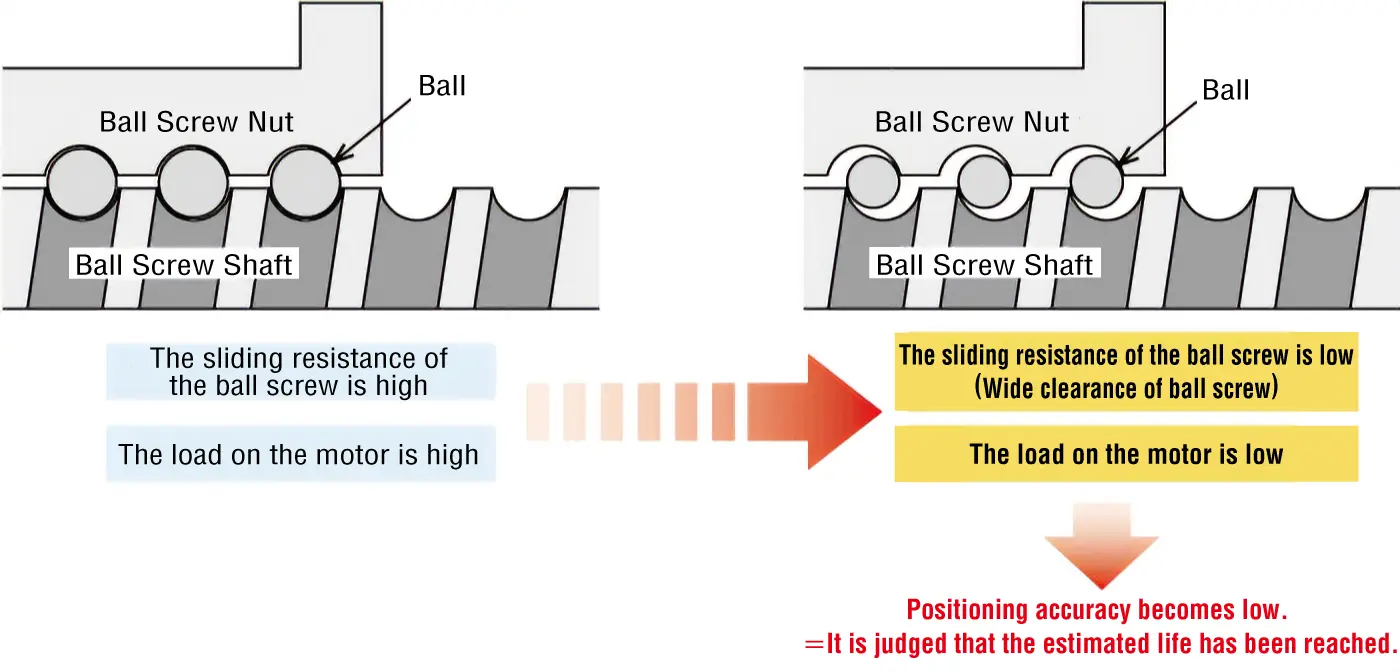

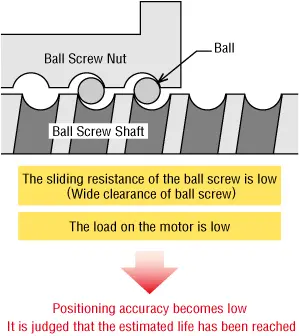

When the ball screw drive is used for positioning operation, the sliding resistance changes from the initial high-accuracy state with pressurization to a lower value due to abrasion of the ball screw over time.

By identifying the correlation between sliding resistance and positioning accuracy, it is possible to replace parts at the appropriate time.

-

At Equipment Start-up (Positioning accuracy: high)

State of high sliding resistance with applied pressure

-

When Used Up to Calculated Lifetime (Positioning accuracy: low)

The ball screw has been subject to abrasion and has low sliding resistance

Products that can constantly monitor the status of the load

Products that Support Maintenance

The following list introduces products and their functions that support maintenance.

Details of Each Series

| Product Category | Series |

|---|---|

| AC Motors | Brake Pack SB50 W |

| Speed Control Motors | DSC |

| Brushless Motors | BMU |

| BLE2 | |

| BLE RS-485 Communication Type | |

| BXII | |

| BLV | |

| BLH RS-485 Communication Type/Digital Setting Type | |

| αSTEP | AR Built-In Controller Type |

| AZ Built-In Controller Type/ Pulse Input Type With RS-485 Communication |

|

| Stepper Motors | RKII |

| PKP/CVD RS-485 Communication Type Driver | |

| Cooling Fan | EMU |

| EMR | |

| MRS | |

| MRE | |

| MD | |

| MBD | |

| MFD |

Reduces Maintenance Load

The use of long life fans can reduce the number of times maintenance is required.

A long life fan capable of maximum 180,000 hours of continuous duty (approx. 20 years) is available.

The number of fan replacements is reduced, resulting in lower overall costs.